CONSTRUCTING THE HARBOUR OF CAESAREA ON THE

SEA: NEW EVIDENCE FROM THE ROMACONS FIELD CAMPAIGN OF OCTOBER 2005.

(A slightly different version was published in The International Journal of

Nautical Archaeology,

2007. 36.2: 409-15)

Background

In approximately one decade (c. 23-15 BCE),

local and Roman builders working for King Herod of Judaea constructed the

largest artificial harbour ever built in the open sea up to that point. The

scale and complexity of this project, along with the rapidity of its execution,

are remarkable even if judged by modern standards. It ranks as one of the most

impressive engineering accomplishments of the Augustan Age (Figure: Aerial

photograph of harbour).

Named Sebastos (the Greek equivalent of

Augustus), the harbour of Caesarea Palaestine, also known in Greek as Caesarea

on the Sea, was

founded on a shifting sand beach devoid of any mitigating physical features.

The shoreline was exposed to the longest fetch in the Mediterranean and scoured

by a strong long-shore current that carried sand from south to north. The site

had been selected primarily for political reasons, not because nature favoured

the construction of a port at this location (Holum and Hohlfelder 1988). Once

the royal decision had been made, it was up to King HerodŐs builders to execute

his desires, even though they faced design and construction challenges never

before encountered by Mediterranean harbour engineers (Hohlfelder, 2000 and

2003). Underwater excavation and exploration have been carried out in the

submerged ruins of HerodŐs vast harbour complex almost continuously since 1960

in an effort to understand how this daunting ancient engineering project was

executed so quickly and expertly in the face of seemingly insurmountable

obstacles. The bibliography on the underwater excavations at Caesarea

Palaestinae is considerable. Most published works relevant to this article are

listed in the references section of Oleson et al. 2004, 228-9.

This archaeological research has produced a vast literature that has revealed

some, but not all, of the secrets of Sebastos.

Since 2002, the Roman Maritime Concrete Study

(ROMACONS) has been conducting fieldwork in Italy, collecting cores from

maritime structures constructed of Roman hydraulic concrete, and building an

underwater reproduction of a pila or pier using materials and tools that would

have been available to Roman builders (Oleson et al., 2004a, 2004b; Hohlfelder et al., 2005; Oleson et al., 2006). So far, we have collected

cores from Roman maritime structures at Portus, Anzio, Cosa, Santa Liberata,

and Baia. Roman hydraulic concrete consisted of a mortar made from lime,

pozzolana (a sand-like volcanic ash naturally rich in aluminosilicates), and

water, to which various types of rubble aggregate was added. The resultant

mixture was a hard and durable concrete that could solidify underwater. While

still in a liquid or plastic state, it could be placed in wooden formwork of

various shapes and sizes to form monolithic masses, including structures known

to the Romans as pilae. The research program of ROMACONS has several aims: to document the

physical and mechanical properties of Roman hydraulic concrete through

exhaustive testing of our sample cores in the laboratories of CTG Italcementi

Group in Bergamo, Italy; to understand the various methods employed by ancient

builders in casting this material in marine environments; to determine the

sources of the ingredients used in its composition; and to identify

geographical or chronological variations in Roman hydraulic concrete during the

six or more centuries it was used in marine constructions throughout the

Mediterranean world.

In

October 2005 ROMACONS was able to extend its research efforts beyond the

Italian peninsula to Israel, where we retrieved five concrete cores from the

extensive remains of concrete blocks that survive from the submerged

installations of King HerodŐs harbour.

It was the first ROMACONS expedition in which all samples were taken

from well below present sea level with the use of SCUBA. Furthermore, Sebastos

is the first imperial harbour that we have sampled in a fairly comprehensive

manner, obtaining cores from a variety of types of structural blocks and from a

judicious spread of locations around the harbour facility. At Antium (Anzio) in

2002 we recovered only a single core, and the five cores taken from the

Claudian and Trajanic installations at Portus at the mouth of the Tiber River

in the same year may not be completely representative of the array of

structures that made up the harbour complex. The five cores taken from the

Republican harbour of Cosa in 2003 represent a more comprehensive sample, but

they were from a smaller, early harbour.

At

Caesarea we were confronted with a plethora of potential targets. Vast numbers of concrete blocks unencumbered

by rubble or post-Classical ruins dot the seafloor. We could only core five

structures, but by careful selection we believed this number would provide a

reasonable sample of the whole. Previous underwater investigations at Caesarea

had revealed at least three different methods employed by ancient builders to

allow the hydraulic concrete to set and cure in a marine environment while

contained within wooden shuttering. Why the builders employed at least three

variants of formwork in different locations in the harbour rather than

standardizing delivery and casting protocols is

unclear at this time. But this creative design is one of the most striking

features of HerodŐs engineering project.

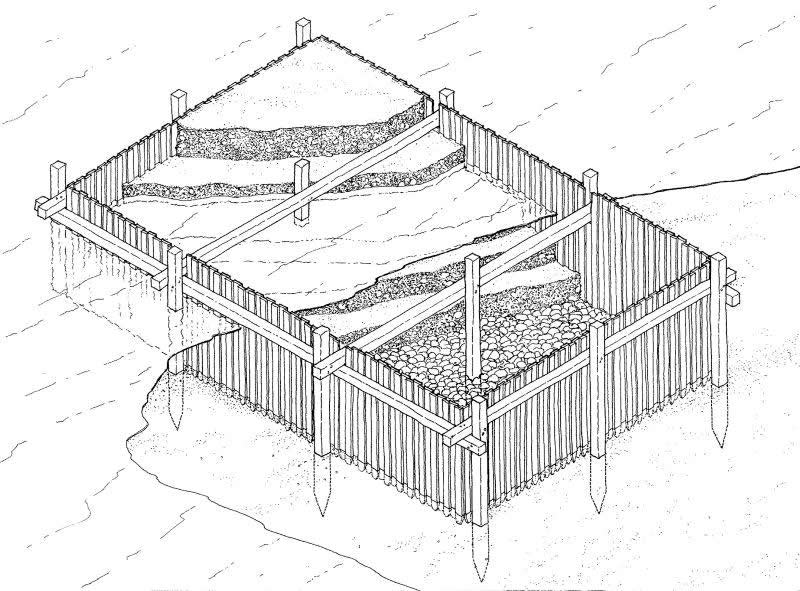

One method employed a box either formed of vertical planks pounded into the ocean floor and then supported by exterior and/or interior horizontal cross beams or by reversing this procedure and pounding the beams in first and affixing the planks to them. (Figure: Vitruvian formwork).

Once the wooden formwork was in place, concrete was placed within

the box to set and then cure. This method was mentioned by Vitruvius, De

Architectura, (c.

25 BCE) and was employed with local variations extensively throughout the Roman

world (Oleson, 1985; Oleson, 1988; Brandon, 1996; Brandon, 1999; and Oleson et

al., 2004a, 2004b, 2006). Three cores were extracted from concrete blocks that

were structural elements of the Southern Breakwater. One (CAE 2005.2) certainly

had been constructed using more or less the Vitruvian method. The other two

(CAE.2005.4 and CAE.2005.5) may have been as well, although their method of

construction has not been absolutely resolved.

The second method, discovered by excavators associated with the Caesarea Ancient Harbour Exportation Project (CAHEP, co-directed by two of the authors – Hohlfelder and Oleson), employed a containment system for the concrete that featured a large double-walled hollow box (c.11x15x4m) that was constructed on shore and towed into position (Figure: Reconstruction of floating form being positioned. Copyright National Geographic Society).

Once in location, the space

between the two walls was filled with mortar until the formwork sank to the

bottom. Only then was it filled with concrete (Oleson, 1985; Oleson, 1988;

Hohlfelder, 1987, 264-5). CAE.2005.03 was taken from the block cast in this

formwork that marked the terminus of the Northern Breakwater- CAHEPŐs Area G

(Oleson, 1989).

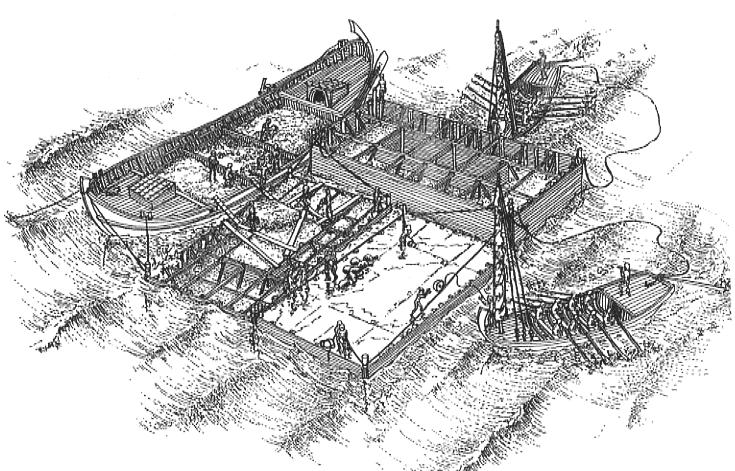

The third method was a variant of the second. Barges built with horizontal planks linked by mortise-tenon joinery were constructed on or near shore and towed into position. We believe that they had most likely been partially filled with concrete in shallow water to reduce their freeboard and susceptibility to the winds and waves and thus facilitate their transport to the desired location. When the barges had been towed to the desired location, they were topped off with concrete until they sank to the bottom (Figure: Reconstruction of barge forms in use. Copyright C. Brandon).

This method of placement has been

studied and discussed extensively by C. Brandon who has conducted underwater

investigations at this site from 1990 to the present in conjunction with the

late Avner Raban and other scholars associated with the University of Haifa A core

was extracted from a block cast in

this method that had been identified by earlier excavators as Area K5

near the terminus of the Northern Breakwater. (Brandon, 1996, 1997, 1998).

The major purpose of our collection of cores was to compare the Caesarea samples to the database that ROMACONS has already amassed from Italian sites. These findings will be published as the results of mechanical and physical tests conducted at the CTG Italcementi laboratory become available. These data will add to our expanding knowledge of the nature and characteristics of hydraulic concrete during its centuries of use by the Romans and the spread of maritime harbour technology throughout the Roman world. The coring equipment and protocols used for collecting these cores have been described in detail elsewhere (Oleson et al., 2004). No major modifications were necessary to complete our fieldwork at Caesarea (Figure: Coring in progress).

ROMACONS 2005 Cores:

Cores were extracted from submerged concrete blocks that were structural elements of the Southern Breakwater and one from the terminus of the northern breakwater that delineates the eastern face of the harbour mouth. (Figure: Aerial of harbour with indication of coring sites).

CAE.2005.01.

06/10/05. K5 on Southern Breakwater.

Depth on top of block: 3.5m. Depth of core hole: 1.10 m.

Total length of core: 1.10m. Proportion recovered: 100%

Comments: Coring stopped when wood was encountered, probably a horizontal tie beam. A cavity left when by an exposed element was visible on the western side of the block. We recovered four solid, joining fragments with no apparent loss of material. The largest fragment was L 0.60 m. The base of the core was rough, and the lowest 0.10 m recovered was moist, as was the top 0.10 m, suggesting inflow through the beam hole. The top of core carried marine incrustation.

CAE.2005.02.

07/10/2005. Block

on Southern Breakwater with tie beam marks on upper surface on CAHEP Survey

Line 3.

Depth on top of block: 3.0 m. Depth of core hole: 1.65 m.

Total length of core: 1.65 m. Proportion recovered: 100%

The coring appeared to have penetrated the entire block, since the

coring tube began to run easily before coring was terminated. Five solid,

joining fragments were recovered; the longest was L 0.59 m, while the shortest

L 0.08. There was no apparent loss of core. The upper and lower ends are darker

green because moist from exposure to sea water.(Figure: View of core CAE.2005.02).

CAE.2005.03.

09/10/2005. Area G on northern breakwater, NW corner edge of block.

Depth on top of block: 3 m. Depth of core hole: 1.00 m.

Total length of core: ca. 0.80m, but most of it was crumbled. Proportion

recovered: ca. 60%

Comments: The core was very fragmentary, either because of the softness of the concrete, or as a result of the action of the coring barrel, which jammed several times in the top 0.10 m. The longest fragment was L 0.15 m. There was kurkar aggregate at the top and bottom of the core; portions of the core seem to have come loose from the mortar during the extraction process only to be ground up by the core bit.

CAE.2005.04.

10/10/2005. Area south of K on southern breakwater.

Depth at top of block: 3 m. Depth of core hole: 2.30-2.40 m.

Total length of core: 2.10 m. Proportion recovered: 91.3%

Comments: The coring penetrated through to the lower surface of the block. There seemed to have been some loss of material at the crumbly section between -1.5 to -1.8 m. There were marine encrustations on both the top and bottom of the core. Nine fragments, largest L 0.60 m; shortest 0.05 m.

CAE.2005.05.

11/10/2005. Area

CO on southern breakwater.

Depth at top of block: 2.5 m. Depth of core hole: 2.0 m

Total length of core: 1.95 m. Proportion recovered: 97.5%

Comments: The irregularity of the upper surface of the block, along with a strong surge, made mounting of the coring frame very difficult. Coring was slowed by the hardness of the kurkar aggregate, and by fragmentation of the upper 0.03 m of the block, which jammed the corer. There was time to take only the 2.0 m recovered.

Analysis

Following a detailed physical inspection in the field the cores are now being studied in the laboratories of Italcementi (Figure: Oleson during field examintion of core).

Tests include

calculation of the ratios of aggregate and mortar; analysis of the composition

of the aggregates to determine particle size and distribution and weights of

each fraction; determination of the dynamic modulus of elasticity and

compressive strength; air void analyses; petrographic analyses of aggregates

and paste fractions; elemental analysis of lime and pozzolana fractions by

X-Ray diffraction and SEM to determine the origin of the materials; and mercury

intrusion porosity tests. While the definitive results of these tests are not

yet available, it is possible to make some general observations about the

Caesarea cores:

CAE.2005.01, 02, 04 and 05 resemble each other

closely in composition and visual appearance. Virtually all the aggregate with

a diameter greater than 0.02 m consists of kurkar, the local carbonate cemented

aeolianite sandstone that occurs throughout the region in ridges parallel to

the modern shoreline. The smaller, non-kurkar aggregate in these cores has

taken on a greenish-blue colour, and most of it has the fibrous appearance of

pumice rather than tuff. Given the absence of large aggregate composed of tuff,

the pumice probably arrived with the bulk shipments of pozzolana as part of the

quarry mix. Numerous similar pumice lapilli appear in the pozzolana deposits around Baia

and Pozzuoli in Italy (the source of the material for Caesarea). During

construction of our experimental pila at Brindisi in 2004 (Hohlfelder et al. 2005; Oleson et al. 2006), many of these lapilli escaped from the wet mortar and

floated to the surface of the water in the form during placement of the

concrete. The exclusive use of local kurkar for aggregate makes economic sense.

Even though this stone served as the caementa, the builders maintained a ratio of aggregate

to mortar similar to that we have found elsewhere. Although the kurkar is porous and sponge-like, our

impression is that the mortar in the Caesarea cores does not adhere as well to

this aggregate as it does to the tuff aggregate used in Italy. Preliminary

analysis indicates that the pozzolana used in the mortar was imported from the

region around Pozzuoli. It has also been determined that the chemical

parameters of the mortar are comparable with our Italian samples, in particular

with our Ňbench-markÓ data from Santa Liberata.

Many of the larger lumps of lime in all five of

these cores show a pattern of thin, alternating black and white stripes, which

we have not seen in cores at other sites. They were most likely formed during

the initial stages of working the pozzolana into the wet lime and consist of

lumps that were chopped or mixed several times in the initial stages of working

but then somehow left unreduced. In general, the visual impression is that

small lumps of unmixed lime are more frequent in the CAE.2005 cores than in

those from the Italian sites we have sampled. Possible explanations are: the

conditions of construction on the open sea either required faster, more

careless preparation of the mortar mix, or the conditions for mixing (on board

ship?) were more difficult; the local workers were less skilled in the

procedure or more diffident than those in Italy. The numerous uniform small

voids also set the CAE.2005 cores apart from those taken in Italy. Perhaps wave

action at the unprotected construction site incorporated bubbles in the mortar

mix during placement, or the construction conditions impeded manual compaction,

or the higher water temperature accelerated the rate of setting and precluded

self-compaction.

The concrete forming CAE.2005.03 is much less

cohesive than that of the other cores, although it seems to have made use of

the same materials. The lumps of unmixed lime may be more frequent in this

sample, suggesting a possible source of weakness, if in fact much of the mix

was poor in lime as a result. It is also possible that rough water conditions

washed out some of the lime before the mix had time to set, or that the mix was

too wet when laid. Another source of weakness could be mechanical damage during

settling of the block. This is a large, relatively thin block, laid on sand. It

is possible that numerous cracks have developed over the last 2000 years,

allowing accelerated weathering throughout the mass.

All of the Caesarea cores were substantially

weaker than the Italian cores that have been tested, CAE.05.01 and 05 showing

less than half the compressive strength of a sample from Santa Liberata

(SLI.04.01). The YoungŐs Modulus (essentially a measure of the internal

cohesion and flexibility of the material) varied significantly among the

samples; it is interesting that CAE.05.01 had a YoungŐs Modulus approximately

equivalent to that of SLI.04.01, while that of CAE.05.05 was only half the

value.

In summary, the concrete at Caesarea, while

constructed with pozzolana from the Bay of Naples, presents a different

appearance than contemporary concretes in Italy, as a result of the distance

from sources of pozzolana and tuff, the location of the construction site on an

unprotected sea shore, and possibly the use of a workforce unaccustomed to

working with hydraulic concrete. Brandon (1999: 173-75) has already commented

on the great variation in the quality of concrete recovered inside the

barge-forms in Area K, near the tip of the southern breakwater. Brandon has

recently calculated that approximately 35,000 cubic m of concrete was used in

the construction of Sebastos, requiring the importation of 24,000 cubic metres

of pozzolana (ca. 52,000

tons), the quarrying of 12,000 cubic m of solid kurkar (to be reduced to rubble before

use), and the production of 12,000 cubic m of slaked lime. The pozzolana alone

would have constituted approximately 100 to 150 large shiploads. Some of these

ships may have been grain freighters that carried grain from Alexandria to

Puteoli (for transhipment to Rome) and then returned with either ballast or a

full cargo of pozzolana. Given the length of this voyage, and possibly the need

to coordinate the construction of the harbour not only with weather and the

more typical supply problems of an enormous project but also with the grain

trade, it would be no surprise if shortages of the crucial pozzolanic additive

developed from time to time. The use of local aggregate must have seemed a

natural decision under these circumstances, but it now seems likely that kurkar was not an adequate substitute for

tuff. This combination of supply problems, inexperience, and a very difficult

construction site resulted in the production of an inferior, but still

remarkably durable, concrete cast in various types of wooden formwork more than

2,000 years ago.

Robert

L. Hohfelder

Department

of History University of Colorado

Boulder,

CO USA

Christopher

Brandon

Pringle

Brandon Architects, 10 Bonhill St.

London

EC2A 4 QJ, UK

John

P. Oleson

Department

of Greek and Roman Studies

University

of Victoria

Victoria

BC V8W 3P4, Canada

Acknowledgements

The directors of ROMACONS are indebted to many people and institutions

for their support and assistance in helping this project become a reality. Dr.

Luigi Cassar of CTG Italcementi Group, Bergamo has encouraged and aided our

research in so many ways since its outset through our fieldwork in 2005. We

also acknowledge and thank his successor, Enrico Borgarello, for continuing to

endorse and assist our project as we look to the future. We are also deeply

grateful to their colleagues, Mr. Dario Belotti, Ms. Isabella Mazza, and Mr.

Massimo Borsa, for providing invaluable logistical support and to Dr. L.

Bottalico, Dr. R. Cucitore, Dr. E.

Gotti and Dr E. Vola for their scientific expertise.

We especially thank Professor Michal Artzy, of the Recanati Institute

for Maritime Studies of the University of Haifa without whose backing this

project would not have been possible. We also acknowledge and thank the help given

by Dr YaŐacov Kahanov, Yossi Tur-Caspa and Amir Yurman for their invaluable

contributions to our fieldwork. We

thank John Tresman, Mosheko Bachar and Omri Ben-Eliyahu for their assistance

and particularly Greg Votruba for his help underwater and his skills as a

photographer.

References

Brandon,

C., 1996, Cements, Concrete, and Settling Barges at Sebastos: Comparisons with

other Roman Harbor Examples and the Descriptions of Vitruvius, in A. Raban and

K. G. Holum (eds), Caesarea Maritima: a Retrospective after Two Millennia, 25–40. Leiden.

Brandon,

C., 1997, The Concrete-Filled Barges of King HerodŐs Harbor of Sebastos, in S.

Swiny, R. L. Hohlfelder, and H. W. Swiny (eds), Res Maritimae: Cyprus and

the eastern Mediterranean from Prehistory to Late Antiquity, 45–58. Atlanta.

Brandon,

C., S. Kemp, and M. Grove, 1999,

Pozzolana, Lime, and Single-mission Barges (Area K), in K. Holum et al. (eds), Caesarea Papers 2, Journal of Roman Archaeology

Supplementary Series 35: 169-172. Portsmouth,

Rhode Island.

Hohlfelder,

R. L., 2000, Beyond coincidence? Marcus Agrippa and King HerodŐs Harbour, Journal

of Near Eastern Studies 59:

241–53.

Hohlfelder,

R.L. 2003. Images of Homage, Images of Power: King Herod and his Harbour,

Sebastos, Antichthon 37:

13-31.

Hohlfelder,

R.L., C. Brandon and J.P. Oleson, 2005. Building a Roman Pila in the Sea—Experimental

Archaeology at Brindisi, Italy, September 2004, International Journal of

Nautical Archaeology

34, 123-27.

Holum, K.G and R.L. Hohlfelder, 1988. King HerodŐs Dream. New York.

Oleson,

J. P., 1985, Herod and Vitruvius: Preliminary Thoughts on Harbour Engineering

at Sebastos, the Harbour of Caesarea Maritima, in A. Raban (ed.), Harbour

Archaeology. Proceedings of the First International Workshop on Ancient Mediterranean

Harbours, Caesarea Maritima,

24–28.6.83, BAR Int. Series

257, 165–72. Oxford.

Oleson,

J. P., 1988, The technology of Roman Harbours, IJNA 17,

147–58.

Oleson,

J.P., 1989, Area G: NW Tip of Northern Breakwater and Adjacent Tower, in A.

Raban (ed.). The Harbours of Caesarea Maritima, Volume 1: The Site and

Excavations, BAR Int. Series 491,

127-30. Oxford.

Oleson, J.

P., C. Brandon, S. Cramer, R. Cucitore, E. Gotti and R.L. Hohlfelder, 2004a.

The ROMACONS Project: A Contribution to the Historical and Engineering Analysis

of Hydraulic Concrete in Roman Maritime Structures, International Journal of

Nautical Archaeology

33, 199-229.

Oleson,

J.P., C. Brandon and R.L. Hohlfelder, 2004b. The Roman Maritime Concrete Study

(ROMACONS): Fieldwork at Portus, Anzio, Santa Liberata, Cosa, 2002-2003, in F.

Maniscalco (ed.), Mediterraneum. Tutela e valorizzazione dei beni culturali

ed ambientali Vol. 4, Tutela del patrimonio culturale sommerso—Protection

of Underwater Cultural Heritage, 185-94. Naples.

Oleson, J. P., L. Bottalico, C. Brandon, R. Cucitore, E. Gotti, and R.L.

Hohlfelder, 2006. Reproducing a Roman Maritime Structure with Vitruvian

Pozzolanic Concrete, Journal of Roman Archaeology 19: 29-52.