Materials

and Design in the Roman Harbour of Soli-Pompeiopolis:

The

ROMACONS Field Campaign of August 2009

To the west

of Mersin, on the southeast Mediterranean coast of Turkey lie the ruins of

Soli/Pompeiopolis, now surrounded by the modern town of Mezitli (Figure 1). The

city has a long maritime history. Initially named

Soloi, the settlement was supposedly founded by Argives following the Trojan

wars and populated by Rhodians from Lindos some four centuries later.

Subsequently it was ravaged during the Mithradatic wars (89 – 81BC) and

eventually abandoned (Strabo 14.5.8). In 67 BC, Pompey the Great restored the

city and colonised it with survivors from his successful campaign against the

Cilician pirates who re-named it Pompeiopolis.

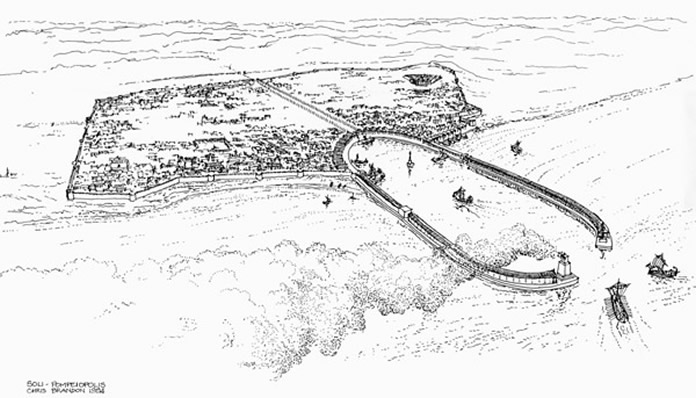

Since the harbour installations visible today date to the Roman period, we will subsequently refer to the site simply as Pompeiopolis. The portion of the harbour still well preserved presents an atypical example of Roman maritime engineering in which well clamped ashlar masonry encases a hydraulic concrete core. Although founded in part on a natural reef, it was largely an artificial harbour laid out to a symmetrical geometric design. The harbour was sheltered by two opposed, curving moles 320m long and approximately 23m wide, set 180m apart. They joined on the landward end in a semicircle. The seaward ends curved inwards to frame the harbour entrance (Figure 2).

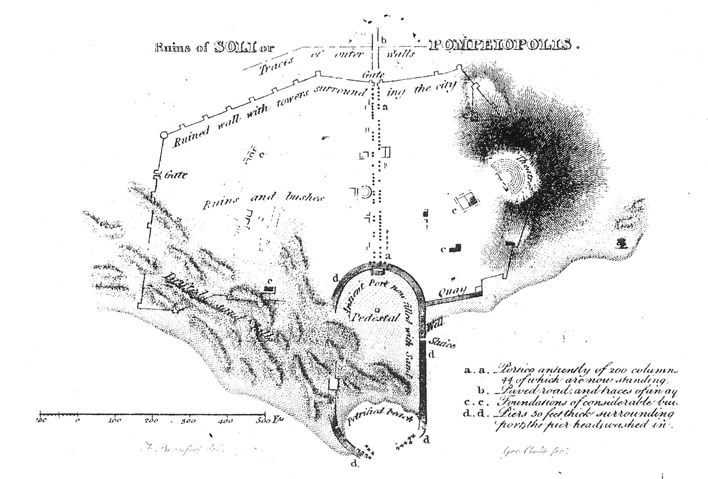

Most of the eastern mole has now disappeared, and the landward half of the moles is now surrounded or covered by silt and sand. The shape of the harbour was first illustrated in the modern era by Sir Francis Beaufort in his book, Karamania, published to accompany his survey of the southern coast of Turkey between 1811 and 1812 (Figure 3; Beaufort, 1817: 248-56).

An ancient, stylised plan of the harbour also appears on a coin struck by Antoninus Pius between 143 and 145 AD (Figure 4)(Boyce, 1958: 67-78).

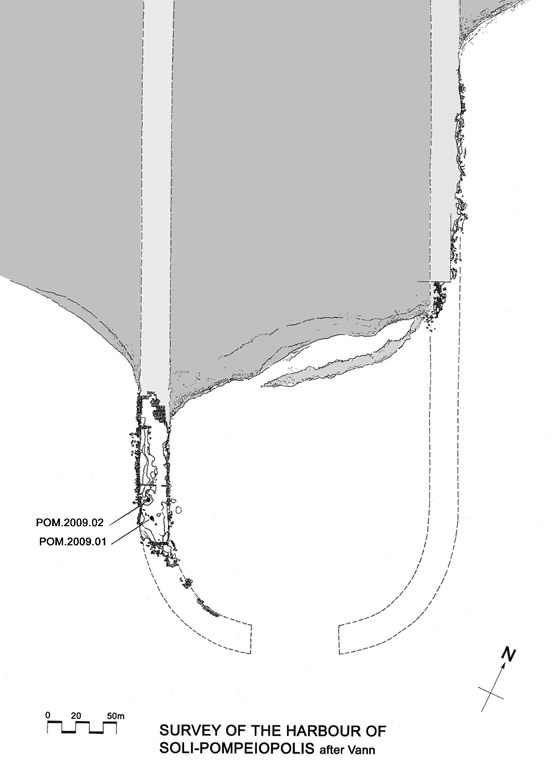

Although the harbour has continued to deteriorate and has in part been built over since it was recorded by Beaufort, it is still possible to make out its plan from aerial photographs, and a substantial section of the western jetty survives in surprisingly good condition (Figures 5, 6).

Beaufort’s plan shows what is called a “sluice” on the eastern mole near

the shoreline of that period. There is now no clear evidence for it, although

Vann suggests that a 3 m gap in the concrete near the present beach restaurant

could be part of it (Vann, 1995: 531). Ancient harbour engineers knew about the

need for flushing devices that would, if properly designed, allow water to flow

through the harbour basin and prevent it from silting up. How effective they

were is a matter of debate. A complicating factor is the possibility that the

Mezitli River (modern name) might once have run through the centre of the

ancient city alongside the colonnaded cardo and flowed into the

harbour with all its accompanying burden of silt. At some point well before

Beaufort’s visit the harbour was completely clogged with sand and fell out of

use. Beaufort’s plan shows it much as it is today, with over three quarters of

the basin landlocked and sand dunes covering most of the western side of the

harbour.

Although the

western mole is the best preserved of the two, only 160 m of the seaward leg is

now visible. The curved seaward head lies in ruins, scattered on the seabed,

while the landward length is buried under the sand and under the road skirting

the ancient basin. The surviving western section, standing in the sea, did so

because it was founded on a natural reef whilst the eastern arm was built on

sand. The absence of a firm foundation allowed its seaward length to collapse

and essentially disappear. The seabed in this area is now strewn with ashlar

blocks and rubble and there is no visible coherent structure.

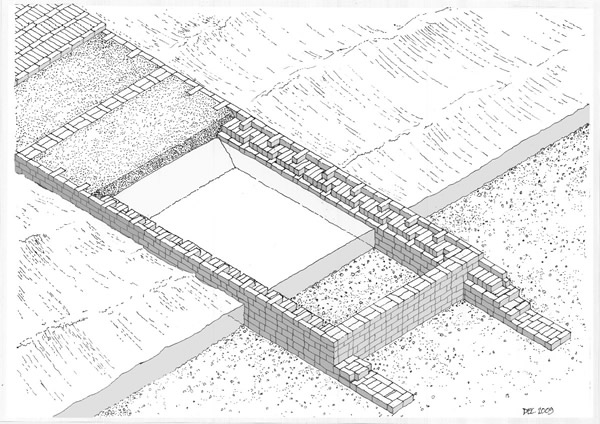

Both moles were composed of large boxes built of ashlar blocks, a type of permanent ashlar formwork filled with hydraulic concrete. The outer faces of the two outside wall were approximately 23 m apart The lower portions of these walls were approximately 2.8 m thick, constructed with approximately uniform stone blocks, 1.6 m long by 0.6 m wide and 0.6 m deep. A well preserved section of the outer wall of the western mole clearly shows the layout of a course of stone blocks (Figure 7).

The design consists of two outer and inner stretcher blocks laid on

either side of five headers followed by a double row of headers. Each block was

secured to the adjacent blocks with enormous butterfly clamps set into the

upper surface of the stone (Figure 8). No clamps have survived, but deep

cuttings 35 cm long, 5 cm deep, and varying in width from 6 cm at the ends to 3

cm at their midpoints. There were up to 6 clamps per block. The size of the

clamp sockets suggests that they were originally wood rather than metal (Vann,

1995:533).

The upper

surface of the western mole is at 1.8 m above sea level, and where stretches of

the original paving stones remain, they are 1.3 m long and 0.63 m wide, laid

out in alternating rows of header and stretcher. Four cross walls are clearly

visible on the exposed surviving length of the western breakwater, are set at

34 m, 30 m, and 14 m apart to form the cells into which the concrete was

placed. Most of the cross-walls are 1.6 m thick, built with alternating courses

of headers and a line of double stretchers alternating with a header. One

cross-wall on the landward end is only 60 cm thick on the upper course,

consisting of a single line of stretchers, whilst it widens to a double row of

stretchers at a lower level. The cells were built out into the sea one by one,

and as each was completed it would have been in-filled with concrete (Figure 9).

This form of enclosure was not watertight and the compartments would have

flooded to sea level, requiring that the lowest stratum of the concrete be laid

underwater. The upper layer of the cells was then filled with a poorer quality

concrete, ultimately paved with stone slabs.

Beaufort’s

plan shows the colonnaded street, part of which is still visible today, running

inland from the harbour along the central axis of the basin. Aerial and land

surveys now show that the street was not on axis with the harbour, off centre

by some 20 m to the east. This was obviously a

deliberate design decision, but one that seems perverse when set in the context

of geometrically symmetry harbour basin. This deviation from symmetry would

make more sense if at some stage the Mezitli river or a canal leading from it

ran through the city and flowed into the harbour.

In

the short time available, the ROMACONS team took two cores on the west

breakwater, using our standard diamond core-drilling rig. We only worked above

water, since the top surface of the mole is currently 1.80 m above sea level.

The structure is so well preserved that we were able to drill down through the

complete height of the structure and well into the bedrock foundation (core

POM.2009.01). The coring was carried out over two days, on the 13th

and 14th August 2009. The first core, POM.2009.01, was drilled 5.7 m

in from the west face of the structure, 13.2 m from cross wall 01, and

approximately 5 m north of a point where bedrock protrudes through the

constructed part of the mole (Figure 10). The upper layers were very difficult

to drill through due to the friable nature of the binding mortar and the very

hard, large aggregate composed of closely packed, smooth riverbed cobbles and

pebbles, circa 15 to 20 cm in diameter.

The

mortar in the top 0.75 m is a poorly mixed, very pale brown material that is

fairly soft, containing much micro-aggregate and many pebbles circa 4-18 mm in

diameter. The micro-aggregate consists of rounded sea or river sand, including

many grains that are red, green, and blue. There are also many white nodules 4

– 8 mm in diameter that are either un-mixed lime or a product of the long

term reaction of the lime with the pozzolana, and also some small fibrous

nodules that could be pumice, brownish yellow in colour. There is a laminar

deposit across the core at a depth of 0.15 m below the top surface, either a product

of the evolution of the mortar, or laitance created during the pour.

From

-0.75-0.95 m the mortar was mostly ground away by the coring, although several

hard river stones remain, and some pumice lapilli, 20-30 mm in diameter.

From

-0.95-1.40 m, the mortar is a very light grey to white, with limestone and

other smooth cobbles as aggregate. There are small fibrous pumice inclusions

and much rounded sand micro-aggregate, some brightly coloured as noted above.

(Figure 11)

At

a depth of -1.35 m there is a rounded lump of volcanic tuff, light greenish

brown in colour with yellow brown inclusions.

From-1.40-2.20

m, the mortar was the same type as above. Although poorly compacted, it

nevertheless is quite hard and varies in colour from white to light green. The

change in colour and composition may have to do with the proximity of the water

level. There are many voids in the material and many large white nodules, along

with lumps of fibrous pumice and particles of green sand, possibly olivine.

Below

-2.20 m the core consists of a yellowish red to pink limestone bedrock with a

layer of very fine mud just above it. It was impossible to determine precisely

where the mud came from, because it infiltrated the core hole each time the

tubes were removed to take out the cores. There are no apparent fissures in the

rock that could have contained the mud, so it probably had been deposited on

top of the bedrock by the river that flowed into the basin or harbour that

preceded the Roman mole.

The

core POM.2009.02 was taken on top of a flat concrete surface 0.49 m above sea

level, and inside the line of the blocks framing the upper part of the mole, 3

m from cross wall 02 and 3.1 m from the western marginal wall outer face

(Figure 12). The level surface seems to be the top surface of the lower level

of hydraulic concrete, exposed by erosion of the upper level of concrete after

the outside ashlar wall was breached at this point. The core hole depth was

0.90 m, although only 0.80 m of material was recovered. The mortar is clearly

pozzolanic in character, even containing some tuff aggregate. This same type of

tuff is seen in the Italian and Caesarea cores, and it probably arrived as an

accidental component of the pozzolana sand shipped from the Puteoli area. The

piece of limestone aggregate that forms the bottom of the core appears

weathered and does not show any traces of adhering mortar, so it probably

represents the bottom surface of this layer of concrete. The core tube went

approximately a metre beyond this point, seemingly going through layers of hard

and soft material, and jamming frequently. Nothing was recovered from this

layer, which may have consisted of a rubble footing.

The mortar is

very homogeneous throughout the core: very hard, well mixed, and clearly

containing much pozzolanic material. The mortar of the upper portion is a

yellowish brown colour, drying to a very pale brown. The mortar contains many

nodules of pumice, 11-18 mm in diameter, and many angular fragments of a white

material, 2-10 mm across, that are either unburned limestone, un-mixed lime, or

a product of the pozzolana-lime reaction that has occurred over time. The

mortar is well compacted, but there are numerous very small spherical voids 1-3

mm across, perhaps resulting from some circumstance during placement, or from

the chemical evolution of the mortar. The aggregate is the same round river bed

limestone cobbles as noted in the first core, with occasional lumps of tuff

23-53 mm in diameter. The tuff also contains nodules of pumice. Wet, the tuff

is greenish blue in colour but dries to a light yellow brown. There is no sign

of the coloured sand particles seen in the upper portion of Core 01. (Figure

13)

From

-0.33 to -0.70 m there is a rapid change in colour of the mortar, to a bluish

green colour or possibly greenish grey, drying to a light greenish grey. At

-0.70 m the mortar returns to its brownish colour. In our other cores of

pozzolanic mortar, the bluish green colour is typical of mortar exposed to sea

water, or kept moist by sea water infiltrating the block.

At

-0.65 a small fragment of a fibrous material, possibly a reed or twig, D 6 mm,

was embedded in the mortar. At -0.75 m a small fragment of wood was embedded in

the surface of the core. Oxford University has carried out a C14 dating

analysis on the organic material recovered from the cores. Calibrated results

suggest that the concrete was placed around 147 AD Ī 48.

After the

cores were extracted, the holes were filled with inert sand and sealed with a

weak hydraulic lime mortar and parts of the top section of the core and river

cobble aggregate, were reinserted as a cap to the filled core holes.

It is

apparent from the initial visual inspection that there are two distinctly

different concretes, the lower layers of a clearly hydraulic material and the

upper layers of a lime or weaker pozzolanic lime mortar. The chemical and thin

section analysis will confirm the specific make up of each. One very marked

difference between the Pompeiopolis concrete and that we have studied at other

sites is in the proportion of large aggregate to mortar. We have seen the

percentages range around 40% aggregate to 60% mortar in the concrete sampled at

sites along the Italian coast, Alexandria and Caesarea, whereas at Pompeiopolis

the percentage varies from 64 to 54% aggregate and 36 to 46% mortar. This ratio

is more akin to that found in Roman terrestrial structures (DeLaine, 1997:123).

In

line with the analysis and mechanical tests that have been carried out on

previous ROMACONS concrete samples; the cores have been taken to Italcementi’s

research laboratories in Bergamo, Italy. The C14 date corresponds well enough

with the date of the coin of Antoninus, suggesting that the coin commemorated a

recently completed project. All the data from the 2009 season will be added to

that collected from earlier work and will be published in a final report that

is currently being prepared.

Acknowledgements

We

wish to thank Dr Remzi Yağci of the Department of Archaeology, Dokuz Eylul

University in Izmir for his assistance and for generously agreeing to support

us with the permit request. This project would have been impossible without the

practical and scholarly assistance of Dr Nicholas Rauh, of Purdue University.

Thanks also go to Dr Enrico Borgarello, of Italcementi who has supported our

research and to his colleagues Mr Dario Belotti, Mrs Isabella Mazza, Dr E

Gotti, and Dr G Vola for their logistical and scientific input. We especially

thank Akin Kaymaz for his assistance in the field.

References

Beaufort,

F., 1817. Karamania, or a brief description of the South Coast of Asia-Minor

and of the Remains of Antiquity. London, esp. pp. 248-256.

Boyce, A.A. 1958. “The Harbour of Pompeiopolis. A Study in Roman

Imperial Ports and Dated Coins,” American Journal of Archaeology 62: 67-78.

DeLaine, J., 1997, The Baths of Caracalla, a study in the design,

construction, and economics of large-scale buildings in imperial Rome, Journal of Roman Archaeology Supplementary Series

Number 25. Portsmouth RI: JRA.

Oleson,

J. P., Brandon, C., Cramer, S. M., Cucitore, R., Gotti, E., and Hohlfelder, R.

L., 2004, “The ROMACONS Project: A Contribution to the Historical and

Engineering Analysis of the Hydraulic Concrete in Roman Maritime Structures,” International

Journal of Nautical Archaeology 33.2: 199-229.

Vann. R.L. 1995. “Survey of ancient Harbours in Turkey: the 1993 Season

at Pompeiopolis,” in XII Arastirma Sonućlari Toplantisi, Ankara, pp. 529-534.

Figures

Figure 1 Location plan

(C. Brandon).

Figure 2 Sketch

impression of the 2nd Century AD harbour (C. Brandon).

Figure 3 Sir

Francis Beaufort’s plan (F. Beaufort 1817).

Figure 4 Antoninus

Coin, Obverse (American Numismatic Society).

Figure 5 Aerial

photograph (Prof. Remzi Yağci).

Figure 6 Plan

of harbour (C. Brandon, L. Vann).

Figure 7 Photograph

of ashlar marginal wall (C. Brandon).

Figure 8 Clamp

cuttings in blocks (J.P. Oleson)

Figure 9 Reconstruction

sketch of concrete laid in ashlar permanent formwork (C. Brandon).

Figure 10 Core

01 in progress (J.P. Oleson).

Figure 11 View

of core 01 (J.P. Oleson)/

Figure 12 Core

02 in progress (A. Kaymaz).

Figure 13 View

of Core 02 (J.P. Oleson).