Mooring Design

& Dynamics

A

Matlab® Package for Designing and Analyzing

Oceanographic Moorings and Towed Bodies

Reference: Marine Models Online, Vol(1), pp 103-157.

Richard K. Dewey

University of Victoria, BC, Canada

RDewey@UVic.CA

Users Guide

Latest Version 2.7 (November 2024)

Mooring Design and Dynamics is a set of Matlab® routines (a toolbox) that

can be used to assist in the design and configuration of single point oceanographic moorings, the

evaluation of mooring tension and shape under the influence of wind and time varying baroclinic currents, and the

simulation of towed bodies. It was originally developed in 1998, and has had a few additions over the years.

It is not truly dynamic, in that at any one time the mooring is assumed to be in

a force balance (not moving), with no un-matched accelerations. The static model will

predict the tension and tilt at each mooring component, including the anchor, for which the safe mass

will be evaluated in terms of the vertical and horizontal tensions. Predictions can be saved to

facilitate mooring motion correction. Time dependent currents can be entered to predict the

dynamic response of the mooring.

Version 2.0 included the capability to predict the depth of towed bodies from

a moving ship with sheared currents, including the use of depressors and tow-floats. Version 2.3 (November 2016)

corrected the entire form and lift drag force formulation and it is strongly recommended that users upgrade to this version.

Version 2.4 (November 2021) needed to update the "plot mooring" routine, which stopped working with more recent versions of Matlab.

Version 2.6 (February 2024) is an essential fix (from v2.5) for surface moorings, and now has all surface floats partially submerged, at a minimum sufficient to provide the necessary buoyancy to keep the top buoy afloat. A new column in the "float" database was added and

is the weight of the float in air. The minimum percentage of float submerged is then the weight in air/buoyancy in water. Old mooring files will use a

nominal fraction of (weight/buoyancy) of 15% (0.15). Users can refine this by editing the database or deleting a float and re-entering with the weight is air.

Version 2.7 fixes a bug in how lift is applied to a tilted cylinder and all wire/rope elements in towed systems.

The package includes a preliminary database of standard

mooring components which can be selected from pull down menus. The database can be edited and

expanded (personalized) to include user specific components, frequently used fasteners/wires etc., or user-specific unique

oceanographic instruments. Once designed and tested, a draft of the mooring components can be plotted

and a list of components, including fasteners can be printed.

Mooring Design and Dynamics is a set of Matlab® routines (a toolbox) that

can be used to assist in the design and configuration of single point oceanographic moorings, the

evaluation of mooring tension and shape under the influence of wind and time varying baroclinic currents, and the

simulation of towed bodies. It was originally developed in 1998, and has had a few additions over the years.

It is not truly dynamic, in that at any one time the mooring is assumed to be in

a force balance (not moving), with no un-matched accelerations. The static model will

predict the tension and tilt at each mooring component, including the anchor, for which the safe mass

will be evaluated in terms of the vertical and horizontal tensions. Predictions can be saved to

facilitate mooring motion correction. Time dependent currents can be entered to predict the

dynamic response of the mooring.

Version 2.0 included the capability to predict the depth of towed bodies from

a moving ship with sheared currents, including the use of depressors and tow-floats. Version 2.3 (November 2016)

corrected the entire form and lift drag force formulation and it is strongly recommended that users upgrade to this version.

Version 2.4 (November 2021) needed to update the "plot mooring" routine, which stopped working with more recent versions of Matlab.

Version 2.6 (February 2024) is an essential fix (from v2.5) for surface moorings, and now has all surface floats partially submerged, at a minimum sufficient to provide the necessary buoyancy to keep the top buoy afloat. A new column in the "float" database was added and

is the weight of the float in air. The minimum percentage of float submerged is then the weight in air/buoyancy in water. Old mooring files will use a

nominal fraction of (weight/buoyancy) of 15% (0.15). Users can refine this by editing the database or deleting a float and re-entering with the weight is air.

Version 2.7 fixes a bug in how lift is applied to a tilted cylinder and all wire/rope elements in towed systems.

The package includes a preliminary database of standard

mooring components which can be selected from pull down menus. The database can be edited and

expanded (personalized) to include user specific components, frequently used fasteners/wires etc., or user-specific unique

oceanographic instruments. Once designed and tested, a draft of the mooring components can be plotted

and a list of components, including fasteners can be printed.

Download MD&D Files from Google Drive.

Installation

The latest version of the matlab toolbox

can be downloaded as a ZIP file, which inlcudes the subroutines, some example moorings files, and the

documentation from

mdd.zip, or visit the Mooring Design and Dynamics web page

for any recent updates and URLs to the

latest files.

The ZIP archives (ZIP and PC self-extracting .EXE) are approximately 2Mb in size.

Extract/copy the files into a local toolbox directory, possibly named

/matlab/toolbox/local/mdd (or what ever directory structure you may have for private toolboxes),

and add this directory to your

Matlab® path.

The programs are started and accessed entirely through a main GUI by

typing/starting »moordesign at the

Matlab® command prompt. To make this Users

Guide accessible from within

Matlab®, the contents of mdddoc.zip must be extracted

under the

Matlab® "help"

directory, in /matlab/help/toolbox/mdd. A Users Guide and model description can then be

accessed from within Matlab® by typing »mdd at the Matlab®

command prompt.

It is not necessary to install the Users Guide to use Mooring Design and Dynamics, but I strongly recommend reading the web version (most up-to-date0 version (here) as the code is old and quirky and most know issues are covered in the Users Guide.

If your

Matlab® path contains blanks, such as

"C:\Program Files\Matlab", then some of the load functions

will/may not work properly. This is because the load command can not have blanks in it. Unfortunately, the

easiest workaround is to install Matlab®

in a path without blanks (ugh!), i.e. "C:\Matlab". What ever...

Mooring Design and Dynamics is a toolbox for the

Matlab® application, and requires a

pre-installed version of Matlab®

to run (it is NOT a stand alone program). The first thing one needs to do, before

using MD&D to assist in the design and evaluation of an oceanographic

mooring, is get organized. One needs a clear definition of the mooring components, it's desired

dimensions, and the environment it will go into. It is suggested the user sketch out the mooring, make

a note of all the major components available, what height above the bottom they are to be deployed at,

what type of fasteners will be used, and what type/size of mooring wire will be used or is available.

All of this information is required before you can complete a mooring design and evaluate it. Then let

MD&D do the actual formal designing, evaluation, and plotting/listing

of the mooring. Alternately, to learn the basics and functionality of MD&D, one can start the program and get familiar with it's capabilities and

what features it has available from it's pull down menus using the example moorings and auxiliary files

provided with the program files. Also, despite the authors efforts, it is possible to enter data and

design moorings that are incompatible with the present code, and the program(s) and routines can be

made to "crash" if data is entered incorrectly. It is assumed the user will try to design meaningful

moorings and follow the suggestions provided here. And as with any development procedure, it is

suggested that you "save early, save often". If you encounter errors or program difficulties, please

"clear all" and reload the mooring. The GUI is "old", pull-down menus may not default to the display option (so always select),

and if there is an "Execute" button, this step (execute) is likely required to save the selections.

Do not assume the program is or the menus are robust to casual executions or error catching.

If problems persist, make sure you have the latest version.

The main menu (MD&D program) is started by typing

>>moordesign;

at the Matlab® command line prompt.

The Main Menu (showing all base options) with active links to each feature is shown

below.

The moorings that can be designed and tested using MD&D

are (at the moment) limited to single point (single anchor) configurations. It is assumed that the user has thought

about the type of mooring, the hardware available to build it, and the environment the mooring will be deployed in.

A rough sketch and/or list of the components and

their anticipated positions along the mooring should be drafted before you begin with

MD&D

. The list of components used by MD&D is intentionally exact (i.e. each

shackle MUST be included). The most common problem I get asked to solve when using MD&D

is that user did not put "connectors" in between mooring elements.

The code needs to know where one element/component ends and the next distinct component begins,

and so just like in a real mooring I insist that the design have connectors (i.e. at least a shackle) between

mooring components. A typical mooring that won't work is: a float, some rope/wire, an instrument, some more rope/wire and an anchor.

The working version of this mooring is: a flaot, a shackle, some rope/wire, a shackle, an instrument, a shackle, more rope/wire,

a shackle, an anchor. This will work. Once designed and tested, the actual list of mooring components (including shackles),

broken down by each different type can be printed, and can actually used as a shopping/packing list.

Moorings are designed from the top down, starting with a float (positive buoyancy

device) and ending with an anchor (negative buoyancy device). Non-sense moorings can be designed, but will have

meaningless solutions or may cause MD&D to crash. It may be necessary to save a

mooring/towed body configuration early, and after a "crash", execute the "Clear All" option from the main menu to clear

memory. Then re-load the file in order to continue. Finally, before deploying a mooring, please read the Disclaimer.

I have added the capability of estimating the tension and fall speed during a free fall

descent (anchor first or last deployments).

This is accomplished by adjusting the uniform (at all depths) vertical velocity (relative to the mooring), until

the weight under he anchor (displayed when a solution is found) is zero (=0). The W associated with this state will be the approximate fall

speed for a free-fall vertically aligned mooring. The tensions in the

wire (which may be large) during a free-fall descent will then be displayed/available.

Warning: This "work-around" does not include any prediction skill while the mooring is adjusting (aligning) to a vertial hang position.

The top (float) of anchor-last free-fall moorings can penetrate to depths

deeper than the static depth, due to inertia and wire angles during release (swinging).

Also, for an anchor-last deployment, the

mooring will not be vertical for the first part of the descent (while the anchor falls/swings below the floats),

and the fall speed solution will not represent this period.

I have heard of the top components of "anchor last" moorings reaching depths deeper than the final vertical alignment/position

of the mooring, so I caution about pushing the pressure ratings of devices too tightly.

The towed bodies that can be designed and tested with MD&D

are of three basic configurations. First is a simple heavy object (net negative buoyancy) and a segment of wire.

However, to facilitate the solution, a virtual "top-of-tow-rope" (floatation) device MUST be placed at the top of the

towed body configuration (see the example in tow001.mat). This is used by the program to "identify" the water surface.

This device has no mass or size, and does not affect the solution, it only assists the program in determining where the

in-water wire and out-of-water wire point is located.

The second type of towed body configuration allowed by MD&D would include a heavy (negative

buoyancy) device(s) (depressor) some where along the tow wire. This is often used to force the towed body to greater depths. The third

configuration has a single floatation (positive buoyancy) device (riser) along the tow

wire, which may or may not break the surface. This is often used to "de-couple" the ship motion from the towed body. In

addition to setting the ship velocity (U=east and V=north), the user

can set the water column velocity profiles [U(z), V(z), W(z)], as might be recorded by an on-board ADCP. Both of these

velocities should be in absolute Earth coordinates (relative to the Earth). Highly

sheared flows will cause the towed body to get pulled far to the side, or even ahead of a slowing moving tow ship.

The user should specify the approximate height (i.e. 5 m) of the towing block (or A-frame) above the water.

This will allow MD&D to estimate the amount of wire out of

the water (from the water surface to the A-frame), which for light towed bodies or high speed tows,

can be significant. The total wire length (from tow body to A-frame) will then be displayed. The size of the towing ship

plotted by MD&D is proportional to the height of the A-frame.

I do not officially provide help. But...

I do want this program to work for you. I have been told the program is "quirky" and takes some getting used to. Do not assume it works

by clicking any oder of buttons and features, as I have not made the code idiot proof.

Follow each menu and sequence methodically, and most information is only "captured" when the "execute" button is

clicked.

It was written when Matlab first released a GUI interface feature (1997), so this represents both Mathworks and my first attempt at a GUI program.

Most of the time I get people contacting me with errors and moorings that don't work, there is a simple explanation.

MD&D assumes the mooring you have "built" through the menu interface is EXACTLY like the real mooring as it will be in the water.

In particular, it MUST have connectors joining the different mooring components.

Therefore both your real-world mooring and the MD&D mooring MUST have (at a minimum) shackles to connect the mooring elements.

MD&D (the code) uses these shackles to know where to break the mathematical solution into segments. Shackles are wonderful things

and it is difficult to use too many. Or at least it is in my code. So, please, make sure you insert a shackle in between every

different mooring component. Then see if you still get errors.

If you do, save the mooring to a MAT file and send it to me.

If I have time, I will try to reproduce the error and see if I can help you fix the problem. If I cannot, oh well, at least you didn't

have to buy MD&D. :)

- Getting Started

- A Word About Moorings

- A Word About Towed Bodies

MD&D

- The Main Menu

- Design New Mooring Initialize a mooring design and all variables.

- Design New Towed Body Initialize a towed body design and all variables.

- Load Existing Mooring/Towed Body Load a previously designed and saved mooring/towed

body.

- Save a Mooring/Towed Body Save the present mooring/towed body.

- Add/Modify In-Line Mooring Elements Add/Edit the present mooring configuration.

- Add/Modify Clamp-on Devices Add/Edit the present mooring/towed body clamp-on devices.

- Add/Modify A Towed Body Add/Edit the present towed body configuration.

- Set/Load Environmental Conditions Set Currents, Wind, Ship velocity.

- Display Currents Display the velocity and density values.

- Evaluate and Plot 3-D Mooring/Towed Body Once designed, evaluated

the mooring under the specified environmental conditions.

- Display Mooring/Towed Body Elements|Print Display (or prints) positions

(and, if evaluated, tensions) of each mooring component and a component summary.

- Plot Mooring|Print Plots (or prints) mooring components.

- Set Desired Depth [m] Enter the desired depth for a towed body, predict the wire

length.

- Add/Examine Elements in Database Edit the mooring component database.

- Make/Load/Show a Movie Make a

Matlab® movie of the mooring forced by time varying currents.

- Clear All Clears all MD&D

variables and figures (state wide re-initialize).

- Whos Displays list of variables, including global matrices.

- Close Close all figures and exit MD&D.

- The Mathematical Solution

- Examples

- Disclaimer

- References

The Main Menu provides access to all the major functions available in MD&D for both moorings (top panel) and towed bodies (low panel).

Initially, however, when no mooring or the necessary environmental

conditions are loaded into memory, only a sub-set of options will be displayed by the Main Menu. These include

the

ability to design a new mooring/towed body, load a mooring/towed body file, and edit/examine the database. As

a mooring or towed body is designed and analyzed, the number of displayed options in the Main Menu increases.

Shown in the top Main Menu figure is a relatively complete Main Menu, showing most functions, after a mooring

has

been loaded. The lower Main Menu figure shows the Main Menu after a Towed Body configuration has been

loaded/designed. These menus are nearly identical, except for the options of plotting the mooring

and making a times series of mooring solutions or movie (available only for moorings),

and the option for specifying the desired depth of the towed body (available on only for towed body

configurations). The size of the Main Menu on your computer screen can be re-sized by dragging one of the corners.

MD&D will then remember this new size the next time it is started.

Design New Mooring Initialize mooring design.

Design New Towed Body Initialize towed body design.

Load Existing Mooring/Towed Body Load a previously designed and saved mooring/towed

body.

Save a Mooring/Towed Body Save the present configuration into a mat file.

Add/Modify In-line Elements Add/Edit the in-line mooring/towed body components.

Add/Modify Clamp-on Devices Add/Edit any clamp-on mooring/towed body components.

Add/Modify A Towed Body Add/Edit the present towed body configuration.

Set/Load Environmental Conditions Set Currents.

Display Currents/Ship Speed Display velocity and density values for moorings,

and in addition for towed bodies, display the ship velocity components (East/North).

for towed bodies.

Evaluate and Plot 3-D Mooring/Towed Body Once designed, a mooring/towed body

can be evaluated under varying environmental conditions.

Display Mooring Elements|Print Display positions (and tensions) of each

mooring component and a component summary.

Add/Examine Elements in Database Edit the mooring component database.

Make/Load/Show a Movie For time varying currents.

Clear All Clears all MD&D variables/figures.

Whos Displays list of all variables (including global).

Close Exit from MD&D and return to MATLAB

command window.

If any of the menu text strings do not fit the menu buttons, or are not legible, then one

can

change the size of the Menu fonts used by MD&D by editing the first

executable line of moordesign.m, fs=12; immediately following the global declarations. An attempt to auto-scale

the

menu font size based on screen resolution is made.

Return to TOC of Users Guide

This function clears

the component list, and presents the user with the "Modify Mooring Design" window. This is the

primary menu/function from which mooring elements can be added (from the database) or deleted to/from

a mooring. By default, mooring elements (components) are added from the top (element one) to the

bottom of the mooring. The top element is usually a floatation device, the bottom element usually an

anchor. All moorings need to have at least some positive buoyancy elements (floatation) and negative

buoyancy elements. Non-sense moorings will likely cause the program to crash. Just as in a real

mooring, components MUST be separated by appropriate fasteners (e.g. shackles), even if the

adjacent mooring components are both wire or rope elements. The intent is to have the solution and list of

mooring components be as complete and accurate as possible, leaving nothing out which is required for

actually building the mooring. Other mooring programs allow you to not specify an anchor, or have

adjacent components without fasteners. MD&D requires you to be

accurate and complete. This forces one to think about the safe operating loads on each component, as

a mooring is only as strong as it's weakest link. A good mooring should have consistent components

(i.e. fasteners) which reflect the anticipated loads and tensions, without wasting over-size

components. Sometimes, due to the dimensions of certain devices, shackles of specific size are

necessary (i.e. the drop shackle for an Interocean Acoustic Release is a 1 inch anchor shackle).

Fitting these specific components with the rest of the mooring may require a series of shackles, and

it is recommended that all of these components be included in the mooring design and analysis. MD&D was designed to do exactly this, producing the most accurate analysis

and complete list of components.

Element to Add/Insert This numeric string is editable

(click on the number with the mouse), and must either be the next "free" element (number of present

elements plus 1, default) to add, or an existing element number to insert a new element and bump the

remaining elements below this.

Delete Element Editable string, where

an existing mooring element number is entered in order to delete this element. You should "click"

Display Elements both before and after deleting an element to confirm the

updated list of mooring elements and their element number.

Component Type: Floatation

(and other mooring component types) This is a pull down menu. Click on the  button to reveal the available list of database component types. They include: Floatation, Wire, Chain and Shackles, Current Meter, Acoustic Release, Anchor, and Component: Misc Instrument. Select a component type by clicking on the name of the type.

Fasteners (shackles and rings) are listed under Chain and Shackles.

61in ORE (and other available mooring components) A pull-down menu to select the

desired mooring component from a list of the available database components for this mooring component

type. Click on the

button to reveal the available list of database component types. They include: Floatation, Wire, Chain and Shackles, Current Meter, Acoustic Release, Anchor, and Component: Misc Instrument. Select a component type by clicking on the name of the type.

Fasteners (shackles and rings) are listed under Chain and Shackles.

61in ORE (and other available mooring components) A pull-down menu to select the

desired mooring component from a list of the available database components for this mooring component

type. Click on the  button to reveal the available list of components, then

click on the desired component. The mooring element list will automatically be updated and displayed

in the Matlab®

Command Window.

Display Elements This button will

re-generate an updated list of the present mooring elements and their respective number in the main

Matlab®

Command Window.

Close Closes this menu, keeping the present

mooring components in memory, and returning to the Main Menu. It would be advisable

to save a complicated mooring after each major modification.

button to reveal the available list of components, then

click on the desired component. The mooring element list will automatically be updated and displayed

in the Matlab®

Command Window.

Display Elements This button will

re-generate an updated list of the present mooring elements and their respective number in the main

Matlab®

Command Window.

Close Closes this menu, keeping the present

mooring components in memory, and returning to the Main Menu. It would be advisable

to save a complicated mooring after each major modification.

Return to The Main Menu

Return to Users Guide TOC

This function clears

the component list (all memory), and presents the user with the "Modify Towed Body Configuration" window.

This is the primary menu/function from which towed body elements can be added (from the database) or deleted

to/from a configuration. By default, towed body elements (components) are added from the bottom (element one)

to

the top of the tow rope. The top element must be the "top-of-tow rope" floatation device, the bottom element

the towed body. All towed bodies need to have at least some negative buoyancy elements and may contain a single

floatation device. Non-sense tow body configurations will likely cause the program to crash. Just as in a real

towed body, components MUST be separated by appropriate fasteners (e.g. shackles), even if the

adjacent components are both wire or rope elements. The intent is to have the solution and list of

components be as complete and accurate as possible, leaving nothing out which is required for

actually building/simulating the towed body.

Three different towed body configurations can be evaluated with MD&D.

These include a simple heavy towed body suspended by a single wire element (see figure above). The

configuration

may be sufficient for most towed body evaluations. An example is stored in the file TOW001.MAT included with

MD&D. The second type of towed body will include a depressor or weight

(negative buoyancy device) at some location along the tow wire

(or more correctly between wire segments). Such a configuration is

shown here on the right and on the

Marlin page at OSU.

The third configuration includes a floatation device at some distance along the tow

wire. Depending on the weight of the tow body, it's drag, the currents and ship speed, the float may or may not

break the surface. Such a spacer is often used to buffer the towed body from ship motion. Once a towed body has been

designed, the following menu is identical to the Modify Towed Body menu.

Element to Add/Insert Bottom-to-Top This numeric string is editable

(click on the number with the mouse), and must either be the next "free" element (number of present

elements plus 1, [default]) to add, or an existing element number to insert a new element and bump the

remaining elements below this. The action is not taken until the "Execute" button is pressed.

Delete Element Editable string, where

an existing towed body element number is entered in order to delete this element. You should "click"

Display Elements both before and after deleting an element to confirm the

updated list of mooring elements and their element number. The delete action is not taken until the "Execute" button is

pressed.

Component Type: Misc Instrument

(and other towed body component types) This is a pull down menu. Click on the  button to reveal the available list of database component types.

Select a component type by clicking on the name of the type.

Fasteners (shackles and rings) are listed under Chain and Shackles.

Component: Heavy Sphere (and other available components) A pull-down menu to select the

desired towed body component from a list of the available database components for this component

type. Click on the

button to reveal the available list of database component types.

Select a component type by clicking on the name of the type.

Fasteners (shackles and rings) are listed under Chain and Shackles.

Component: Heavy Sphere (and other available components) A pull-down menu to select the

desired towed body component from a list of the available database components for this component

type. Click on the  button to reveal the available list of components, then

click on the desired component. The list of component will not be updated until the "Execute" button is pressed. The "Heavy

Sphere" in the default database, represents a test device for towed bodies. It is a sphere with net negative buoyancy

(sinks), and can be used as a template for other simple towed bodies.

Enter Ship Velocity [U V] (m/s) This is where the user specifies and changes the ship velocity

for the towed body. The ship velocity is assumed to be in Earth coordinates, with U = East velocity and V = North velocity,

both given in metres per second (m/s). Note that 1 knot is 0.514 m/s. Use MATLAB (or other calculator) to convert a speed

and compass direction to components using "speed*exp(i*(90-heading)*pi/180)", where heading is clockwise from true north and

U is the real part and V is the imaginary part of the answer. NOTE: If the water column velocity profile is given in

absolute velocities relative to the Earth (i.e. navigated ADCP data), then the ship velocity is the velocity OVER LAND (i.e. as reported by a GPS navigation system. If the water column velocity is not know, or set to zero (default), then the

important ship velocity is that relative to the surface water. If both are absolute (i.e. relative to land), then they will

give the same result. For example, a ship moving in the X (East) direction at one knot, is equivalent to a stationary ship

in a U=-0.514 m/s current.

Height of A-Frame Block Above Water (m) This number sets the scale of the ship, and also

determines the length of wire out of the water, from the surface to the A-frame block. For light tow bodies, or fast towing,

there can be a significant amount of wire out of the water, be tween the surface and the block.

MD&D will estimate this length of wire, so that the reported wire length is from the block to the towed body. No

wind drag is calculated in the "out-of-water" wire, so a hanging catenary shape is assumed. As with the

real world, the angle of the towed body from the ship pivots at the block. If the height of the A-

frame is set to zero, no ship is plotted (ship size scales with A-frame height).

Execute Add-Insert-Delete Operation Once the component has been selected for addition, insertion,

or deleting, this button executes the procedure.

Display Elements This button will

generate a list of the present towed body elements and their respective number in the

Matlab® Command Window.

Close Closes this menu, keeping the present towed body

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated towed body after each major modification.

button to reveal the available list of components, then

click on the desired component. The list of component will not be updated until the "Execute" button is pressed. The "Heavy

Sphere" in the default database, represents a test device for towed bodies. It is a sphere with net negative buoyancy

(sinks), and can be used as a template for other simple towed bodies.

Enter Ship Velocity [U V] (m/s) This is where the user specifies and changes the ship velocity

for the towed body. The ship velocity is assumed to be in Earth coordinates, with U = East velocity and V = North velocity,

both given in metres per second (m/s). Note that 1 knot is 0.514 m/s. Use MATLAB (or other calculator) to convert a speed

and compass direction to components using "speed*exp(i*(90-heading)*pi/180)", where heading is clockwise from true north and

U is the real part and V is the imaginary part of the answer. NOTE: If the water column velocity profile is given in

absolute velocities relative to the Earth (i.e. navigated ADCP data), then the ship velocity is the velocity OVER LAND (i.e. as reported by a GPS navigation system. If the water column velocity is not know, or set to zero (default), then the

important ship velocity is that relative to the surface water. If both are absolute (i.e. relative to land), then they will

give the same result. For example, a ship moving in the X (East) direction at one knot, is equivalent to a stationary ship

in a U=-0.514 m/s current.

Height of A-Frame Block Above Water (m) This number sets the scale of the ship, and also

determines the length of wire out of the water, from the surface to the A-frame block. For light tow bodies, or fast towing,

there can be a significant amount of wire out of the water, be tween the surface and the block.

MD&D will estimate this length of wire, so that the reported wire length is from the block to the towed body. No

wind drag is calculated in the "out-of-water" wire, so a hanging catenary shape is assumed. As with the

real world, the angle of the towed body from the ship pivots at the block. If the height of the A-

frame is set to zero, no ship is plotted (ship size scales with A-frame height).

Execute Add-Insert-Delete Operation Once the component has been selected for addition, insertion,

or deleting, this button executes the procedure.

Display Elements This button will

generate a list of the present towed body elements and their respective number in the

Matlab® Command Window.

Close Closes this menu, keeping the present towed body

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated towed body after each major modification.

Return to The Main Menu

Return to Users Guide TOC

Opens an operating system window, similar to the one shown here, from which

the user can select a disk, directory, and MAT file containing a previously saved

mooring or data. This same window is used to load a previously saved movie of a

time dependent mooring simulation or environmental data. Some default and test

moorings and movies are included with this package (including least the list shown here), with some

time dependent current profiles moorings (*ts.mat). Click on (highlight) the desired file and then

click

Opens an operating system window, similar to the one shown here, from which

the user can select a disk, directory, and MAT file containing a previously saved

mooring or data. This same window is used to load a previously saved movie of a

time dependent mooring simulation or environmental data. Some default and test

moorings and movies are included with this package (including least the list shown here), with some

time dependent current profiles moorings (*ts.mat). Click on (highlight) the desired file and then

click  , or double click on the filename (depending on the operating system).

, or double click on the filename (depending on the operating system).

Return to The Main Menu

Return to Users Guide TOC

Opens an operating

system window, similar to the one shown here, from which the user can select a disk, directory, and

MAT filename into which all necessary mooring information or environmental data

is saved. This mat file can then be loaded later to further evaluate, view,

modify, or analyze the mooring. Click on an existing filename to overwrite, or enter the filename.

This list shows some of my mooring designs from a project in Juan de Fuca in 1997, including three

thermistor chain and two ADCP moorings. Time series of current profiles recorded by the ADCPs where

then used to "simulate" mooring motion. The thermistor depths where then corrected. These "weakly"

taut moorings had 15 m excursions during peak (1.2 m/s) currents, which where simulated to within 1%

of the recorded top and bottom pressure records.

Opens an operating

system window, similar to the one shown here, from which the user can select a disk, directory, and

MAT filename into which all necessary mooring information or environmental data

is saved. This mat file can then be loaded later to further evaluate, view,

modify, or analyze the mooring. Click on an existing filename to overwrite, or enter the filename.

This list shows some of my mooring designs from a project in Juan de Fuca in 1997, including three

thermistor chain and two ADCP moorings. Time series of current profiles recorded by the ADCPs where

then used to "simulate" mooring motion. The thermistor depths where then corrected. These "weakly"

taut moorings had 15 m excursions during peak (1.2 m/s) currents, which where simulated to within 1%

of the recorded top and bottom pressure records.

Return to The Main Menu

Return to Users Guide TOC

As with Designing a New Mooring, this is the primary working menu used to modify (add and

delete) in-line mooring elements from a mooring. More mooring components will be "in-line". These components

are

distinguished from "clamp-on" devices, which would commonly be attached to a wire/rope segment.

Element to Add/Insert. This numeric string is editable

(click on the number with the mouse), and must either be the next "free" element (number of present

elements plus 1, default) to add, or an existing element number to insert a new element and bump the

remaining elements below this.

Delete Element Editable string, where

an existing mooring element number is entered in order to delete this element. You should "click"

Display Elements both before and after deleting an element to confirm the new

list of mooring elements and their element number.

Load Different Database This option allows a user to maintain a variety of

databases,

and

load a new or user specific database of mooring components as necessary. When loaded, the component type and

components displayed in the following menu items may change.

Current Meter (and

other mooring component types) This is a pull down menu. Click on the  button

to reveal the available list of database component types. They include: Floatation,

Wire, Chain and Shackles, Current Meter, Acoustic Release, Anchor, and Misc

Instrument. Select a component type by clicking on the name of the type. Fasteners

(i.e. shackles, rings, swivels, etc.) are listed under Chain and Shackles.

Aanderaa RCM-7 (and

other mooring components) A pull-down menu to select the desired mooring component from a list of the

available database components for this mooring component type. Click on the

button

to reveal the available list of database component types. They include: Floatation,

Wire, Chain and Shackles, Current Meter, Acoustic Release, Anchor, and Misc

Instrument. Select a component type by clicking on the name of the type. Fasteners

(i.e. shackles, rings, swivels, etc.) are listed under Chain and Shackles.

Aanderaa RCM-7 (and

other mooring components) A pull-down menu to select the desired mooring component from a list of the

available database components for this mooring component type. Click on the  button to reveal the available list of components, then click on the component. The mooring element

list will automatically be updated once this component has been selected.

Execute Update Push this button to execute the desired update to the in-line mooring

components once the index, type and device have been selected. This was added as a confirmation and a safe guard

to

minimize errors in changing moorings.

Display Elements This button will

generate a list of the present mooring elements and their respective number in the main Matlab®

Command Window.

Global Replace This option allows a user to globally replace/substitute one type

of mooring component with another from the database. Selecting this option brings up the

Global Replace menu. Both in-line and clamp-on devices can be universally replaced.

Close Closes this menu, keeping the present mooring

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated mooring after each major modification.

button to reveal the available list of components, then click on the component. The mooring element

list will automatically be updated once this component has been selected.

Execute Update Push this button to execute the desired update to the in-line mooring

components once the index, type and device have been selected. This was added as a confirmation and a safe guard

to

minimize errors in changing moorings.

Display Elements This button will

generate a list of the present mooring elements and their respective number in the main Matlab®

Command Window.

Global Replace This option allows a user to globally replace/substitute one type

of mooring component with another from the database. Selecting this option brings up the

Global Replace menu. Both in-line and clamp-on devices can be universally replaced.

Close Closes this menu, keeping the present mooring

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated mooring after each major modification.

Return to The Main Menu

Return to Users Guide TOC

As with In-Line Elements, this menu is used to add/modify any clamp-on mooring components. Such

components

would most naturally (in the real world) be attached to a wire or rope segment. However, This program allows

the

user

to specify the height of the desired component above the bottom, and the program will determine which in-line

mooring

component the clamp-on device is attached.

Clamp-on Device to Add/Insert. A separate list of clamp-on devices is stored, and

this

index is a non-sequential pointer to the clamp-on devices. When the mooring components are

displayed, a separate list is displayed if there are any clamp-on devices. Each clamp-on

device is

listed with it's index, and this displayed index should be used with adding/deleting clamp-on devices.

Usually,

this

index is incremented, but the device heights may not be sequential.

Delete Clamp-on Element Editable string, where

an existing clamp-on device number (index) is entered in order to delete this device. The deletion is not

executed until the "Execute Update" button is pushed. You should "click"

Display Elements both before and after deleting an element to confirm the new

list of mooring elements/clamp-on devices and their associated element number/index.

Load Different Database This option allows a user to maintain a variety of

databases,

and

load a new or user specific database of mooring components as necessary. When loaded, the component type and

components displayed in the following menu items may change.

Misc Instrument (and

other mooring component types) This is a pull down menu. Click on the  button

to reveal the available list of database component types.

Branker TR1000 (and

other mooring components/devices) A pull-down menu to select the desired mooring component from a list of the

available database components for this mooring component type. Click on the

button

to reveal the available list of database component types.

Branker TR1000 (and

other mooring components/devices) A pull-down menu to select the desired mooring component from a list of the

available database components for this mooring component type. Click on the  button to reveal the available list of components, then click on the component. The mooring component

lists will be updated only after the "Execute Update" button is pushed.

Display Elements This button will

generate a list of the present mooring elements and their respective number in the main Matlab®

Command Window.

Execute Update Once selected, this button incorporates the changes

(additions/deletions)

into the mooring array.

Close Closes this menu, keeping the present mooring

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated mooring after each major modification.

button to reveal the available list of components, then click on the component. The mooring component

lists will be updated only after the "Execute Update" button is pushed.

Display Elements This button will

generate a list of the present mooring elements and their respective number in the main Matlab®

Command Window.

Execute Update Once selected, this button incorporates the changes

(additions/deletions)

into the mooring array.

Close Closes this menu, keeping the present mooring

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated mooring after each major modification.

Return to The Main Menu

Return to Users Guide TOC

As with In-Line Elements,

this menu is used to add/modify in-line components associated with a towed body. Such components

would most naturally (in the real world) include the towed body, fasteners, wire/rope, and the mandatory

"top-of-tow-rope" device. Three towed body configurations are possible in MD&D.

First is a simple towed body, with a body, wire, and "top-of-tow-rope" device (The "top-of-tow-rope" device is necessary as,

the wire actually continues out of the water to the block at the A-frame, but MD&D needs to

know where the surface is. The second available configuration would include a "heavy" (sinking) weight at some distance

along the tow wire. This configuration is sometimes used to force a towed device to depths deeper than would be

accomplished without the weight. The third configuration involves placing a "float" along the tow wire, effectively de-

coupling the towed body from any pitching and heaving of the ship. MD&D allows for a single

in-line float. Multiple floats will confuse the program, as it needs to split the mathematical solution into two parts

(ahead-of and behind the float).

Element to Add/Insert. This editable number specifies the next towed body element to add or

modify in the configuration. For towed bodies, the program works from the bottom (towed body) to the top (top-of-tow-rope).

Usually, the index is incremented to be one larger than the number of elements presently in the tow line. The addition is

not preformed until the "Execute" button is pressed.

Delete Element Editable string, where

an existing towed body component number (index) is entered in order to delete this device. The deletion is not

executed until the "Execute Update" button is pushed. You should "click"

Display Elements both before and after deleting an element to confirm the new

list of mooring elements/clamp-on devices and their associated element number/index.

Load Different Database This option allows a user to maintain a variety of

databases, and load a new or user specific database of mooring/towed body components as necessary. It might be desireable to

maintain separate databases for towed bodies and moorings, especially if the database(s) becomes large.

When loaded, the component type and components displayed in the following menu items will change.

Component Type: Floatation (and

other towed body component types) This is a pull down menu. Click on the  button

to reveal the available list of database component types.

Component: Top of Tow Rope (and

other towed body components/devices) A pull-down menu to select the desired component from a list of the

available database components for this component type. Click on the

button

to reveal the available list of database component types.

Component: Top of Tow Rope (and

other towed body components/devices) A pull-down menu to select the desired component from a list of the

available database components for this component type. Click on the  button to reveal the available list of components, then click on the component. The working mooring component

lists will be updated only after the "Execute" button is pressed.

Change Length of Wire Element # For a towed body, the most common change will simply be a

lengthening or shortening of the tow rope. To facilitate this change, rather than deleting and adding a new wire/rope

element each time, the user can select the wire/rope element to change (the element number is listed in the Command Window

when the Display Elements button is pressed), and then puss this button to change the wire/rope

length. A new window will open from which the user can edit the wire length.

Enter Ship Velocity [U V] (m/s) This is where the user specifies and changes the ship velocity

for the towed body. The ship velocity is assumed to be in Earth coordinates, with U = East velocity and V = North velocity,

both given in metres per second (m/s). Note that 1 knot is 0.514 m/s. Use MATLAB (or other calculator) to convert a speed

and compass direction to components using "speed*exp(i*(90-heading)*pi/180)", where heading is clockwise from true north and

U is the real part and V is the imaginary part of the answer. NOTE: If the water column velocity profile is given in

absolute velocities relative to the Earth (i.e. navigated ADCP data), then the ship velocity is the velocity OVER LAND (i.e. as reported by a GPS navigation system. If the water column velocity is not know, or set to zero (default), then the

important ship velocity is that relative to the surface water. If both are absolute (i.e. relative to land), then they will

give the same result. For example, a ship moving in the X (East) direction at one knot, is equivalent to a stationary ship

in a U=-0.514 m/s current.

Height of A-Frame Block Above Water (m) This number sets the scale of the ship, and also

determines the length of wire out of the water, from the surface to the A-frame block. For light tow bodies, or fast towing,

there can be a significant amount of wire out of the water, be tween the surface and the block.

MD&D will estimate this length of wire, so that the reported wire length is from the block to the towed body. No

wind drag is calculated in the "out-of-water" wire, so a hanging catenary shape is assumed. As with the

real world, the angle of the towed body from the ship pivots at the block. If the height of the A-

frame is set to zero, no ship is plotted (ship size scales with A-frame height).

Execute Add-Insert-Delete Operation Once the component has been selected for addition, insertion,

or deleting, this button executes the procedure.

Display Elements This button will

generate a list of the present towed body elements and their respective number in the

Matlab® Command Window.

Close Closes this menu, keeping the present towed body

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated towed body after each major modification.

button to reveal the available list of components, then click on the component. The working mooring component

lists will be updated only after the "Execute" button is pressed.

Change Length of Wire Element # For a towed body, the most common change will simply be a

lengthening or shortening of the tow rope. To facilitate this change, rather than deleting and adding a new wire/rope

element each time, the user can select the wire/rope element to change (the element number is listed in the Command Window

when the Display Elements button is pressed), and then puss this button to change the wire/rope

length. A new window will open from which the user can edit the wire length.

Enter Ship Velocity [U V] (m/s) This is where the user specifies and changes the ship velocity

for the towed body. The ship velocity is assumed to be in Earth coordinates, with U = East velocity and V = North velocity,

both given in metres per second (m/s). Note that 1 knot is 0.514 m/s. Use MATLAB (or other calculator) to convert a speed

and compass direction to components using "speed*exp(i*(90-heading)*pi/180)", where heading is clockwise from true north and

U is the real part and V is the imaginary part of the answer. NOTE: If the water column velocity profile is given in

absolute velocities relative to the Earth (i.e. navigated ADCP data), then the ship velocity is the velocity OVER LAND (i.e. as reported by a GPS navigation system. If the water column velocity is not know, or set to zero (default), then the

important ship velocity is that relative to the surface water. If both are absolute (i.e. relative to land), then they will

give the same result. For example, a ship moving in the X (East) direction at one knot, is equivalent to a stationary ship

in a U=-0.514 m/s current.

Height of A-Frame Block Above Water (m) This number sets the scale of the ship, and also

determines the length of wire out of the water, from the surface to the A-frame block. For light tow bodies, or fast towing,

there can be a significant amount of wire out of the water, be tween the surface and the block.

MD&D will estimate this length of wire, so that the reported wire length is from the block to the towed body. No

wind drag is calculated in the "out-of-water" wire, so a hanging catenary shape is assumed. As with the

real world, the angle of the towed body from the ship pivots at the block. If the height of the A-

frame is set to zero, no ship is plotted (ship size scales with A-frame height).

Execute Add-Insert-Delete Operation Once the component has been selected for addition, insertion,

or deleting, this button executes the procedure.

Display Elements This button will

generate a list of the present towed body elements and their respective number in the

Matlab® Command Window.

Close Closes this menu, keeping the present towed body

components in memory, and returning control to the Main Menu. It would be advisable to save a complicated towed body after each major modification.

Return to The Main Menu

Return to Users Guide TOC

This menu allows a user to make global or wholesale changes to the mooring components of an existing mooring.

This menu allows a user to make global or wholesale changes to the mooring components of an existing mooring.

Display Elements button lists in the main Matlab command window all mooring

components and a summary or tally of how

many of each different type of mooring component is included. For wire and rope components, the total length

of material is displayed, even if this is divided into multiple segments in the mooring.

Change All. The mooring summary list is accessible from the Change All pull down

menu, from which the user can select a mooring component that has multiple occurrences, and then select an

alternate component to replace these.

Use the Type and Component menus to select the new

component (e.g. globally replace 1/2'' shackles with 5/8" shackles) .

The change does not occur until the Change button is pressed. Be careful, it is

possible to remove major

components, (e.g. floats) and globally replace them with inappropriate device types (e.g.

anchors). The available mooring components displayed are from the default database file (mdcodes.mat).

The Close button closes this global change window and sends control back to the

Modify Elements window.

Return to Modify Mooring

Return to The Main Menu

Return to Users Guide TOC

Enter/Edit Velocities Manually to enter the velocities [U(z), V(z), W(z) and z]

using the keyboard.

Load / Save Velocity File If velocity profile data has

already been entered and/or saved, it can/should be reloaded or saved at this time.

Enter / Edit Densities Manually Enter or Load a density [kg/m3] profile.

The mooring solution depends very weakly on density, but if it is important, one can modify it.

Load / Save Density File If density profile data has

already been entered and/or saved, it can/should be reloaded or saved at this time.

Enter Winds Allows the user to specify a surface wind, which will apply an extra

velocity kick (2% of wind speed) to the upper ocean current speeds.

Help brings up a simple text window with a brief description of the types of

environmental data which can

be entered.

Enter/Edit Velocities Manually to enter the velocities [U(z), V(z), W(z) and z]

using the keyboard.

Load / Save Velocity File If velocity profile data has

already been entered and/or saved, it can/should be reloaded or saved at this time.

Enter / Edit Densities Manually Enter or Load a density [kg/m3] profile.

The mooring solution depends very weakly on density, but if it is important, one can modify it.

Load / Save Density File If density profile data has

already been entered and/or saved, it can/should be reloaded or saved at this time.

Enter Winds Allows the user to specify a surface wind, which will apply an extra

velocity kick (2% of wind speed) to the upper ocean current speeds.

Help brings up a simple text window with a brief description of the types of

environmental data which can

be entered.

Return to The Main Menu

Return to Users Guide TOC

The Enter

buttons bring up (yet) another menu

which allows the user the type in a string of delineated (spaces, commas) values for each of the

desired profiles [e.g. U(z) and z], each with the exact same number of values, starting from the top

(surface) value to the bottom value, which is ALWAYS associated with z(n)=0 meters, where n is the

total number of values making up the velocity profile(s). By default the V(z) and W(z) profiles are

set to zeros. The height of the velocity and density profiles determines the water depth which the

mooring is in.

Save Velocities Opens a system window (section 1.3) to save the

velocity (environmental) data into a standard

Matlab® mat file. This same environmental

data can be re-loaded using the Load Environmental Conditions option (section 1.5).

Help opens a simple text window with simple instructions as to how to enter meaningful velocity

profile data as a text string (i.e. current values in m/s from top to bottom, where a bottom must

be entered at z=0).

The Enter

buttons bring up (yet) another menu

which allows the user the type in a string of delineated (spaces, commas) values for each of the

desired profiles [e.g. U(z) and z], each with the exact same number of values, starting from the top

(surface) value to the bottom value, which is ALWAYS associated with z(n)=0 meters, where n is the

total number of values making up the velocity profile(s). By default the V(z) and W(z) profiles are

set to zeros. The height of the velocity and density profiles determines the water depth which the

mooring is in.

Save Velocities Opens a system window (section 1.3) to save the

velocity (environmental) data into a standard

Matlab® mat file. This same environmental

data can be re-loaded using the Load Environmental Conditions option (section 1.5).

Help opens a simple text window with simple instructions as to how to enter meaningful velocity

profile data as a text string (i.e. current values in m/s from top to bottom, where a bottom must

be entered at z=0).

Back to Load Environmental Conditions

Return to The Main Menu

Return to Users Guide TOC

Enter the velocity values

in m/s separated by either spaces or commas, as a text string starting with the top (highest) value and

ending with the velocity value at the bottom (z=0), which in most cases should be 0 m/s. There is no

limit to the number of velocity values in a profile. Alternately, view the contents of the provided velocity

mat files included with the package to see the data format, and make/load you own velocity data from

the keyboard, a model, or measured currents and save these into a mat file. The displayed values make

up the default velocity profile with speeds of 1.0, 0.6 and 0 m/s, respectively.

OK will accept

these values and potentially bring up the Enter Heights menu.

Help

displays a simple text window of help for entering the velocity profile data.

Back to Load Environmental Conditions

Return to The Main Menu

Return to Users Guide TOC

Enter the height values in m for the associated velocity data,

separated by either spaces or commas, as a text string starting with the top (highest) value and ending at

the bottom (z=0). The number of Z values must be the same as the number of velocity values already

entered. Alternately, view the variables in the provided velocity mat file (vel001.mat) included with the

package to see the

data vector format, and make/load you own velocity and density profile data from the keyboard, a

model, or measured values and save these into an appropriately named mat file. The displayed values

are the default heights: 120, 10 and 0 meters.

OK will accept these values.

Help displays

a simple text window of help for entering the velocity profile data.

Back to Load Environmental Conditions

Return to The Main

Menu

Return to Users Guide TOC

Enter either the density values or the height values for the density profile.

The solution needs a local density value, so you can enter a specific density structure, or default

to a simple stratified ocean [1024 kg/m3 at surface 1026 kg/m3 at bottom].

Save Density Profile brings up the save

Matlab® file menu for saving the density

profile data for future retrieval.

Help brings up a simple text window describing the minimum

data entry procedures for entering density profile data as a space or comma delineated text string.

Back to Load Environmental Conditions

Return to The Main Menu

Return to Users Guide TOC

Enter either the density values or the height values for the density profile as

text strings procedures by either spaces or commas. The solution needs a local density values (stored

in vector/variable "rho"), so you can enter a specific density structure, or default to a simple linearly

stratified ocean [1024 kg/m3 at surface, 1026 kg/m3 at bottom].

OK brings

up a similar window to enter or edit the heights for the density values.

Help brings up a

simple text window describing the minimum data entry procedures for entering density profile data as

a space or comma procedures text string.

Back to Load Environmental Conditions

Return to The Main Menu

Return to Users Guide TOC

Enter the wind speed [m/s] and direction [degrees from North in

meteorological convention, i.e. the direction from which the wind is blowing]. The 2% velocity "kick"

penetrates to depths below the surface at approximately 1 m for every m/s of wind speed (regardless

of the density profile), so a 10 m/s wind penetrates an additional linearly decreasing velocity

profile down about 10 m in the direction of the wind (no Ekman spiral). The maximum wind penetration

is 80% of the water column, assuming that a bottom boundary layer will exist within which wind

forcing is negligible/dampened.

OK returns and stores the surface wind vectors (in East and

North components).

Help brings up a simple text window describing the minimum data entry

procedures for entering environmental data.

Back to Load Environmental Conditions

Return to The Main Menu

Return to Users Guide TOC

Pressing this button will display the current velocity and density profile values

in the main Matlab®

Command Window. To plot these profiles, one can simply enter regular

Matlab®

plotting commands at the command prompt. I have not included a profile plotting set of routines in

this package since there are many ways to present such data, and most oceanographic users will have

specific needs and desires with regard to their hydrographic and velocity data. A set of simple

plotting commands might look like:

>> figure

>> plot(U(:,1),z,'r',V(:,1),z,'b');

>> xlabel('Velocities U=red, V=blue [m/s]');

>> ylabel('Height Above Bottom [m]');

Return to The Main Menu

Return to Users Guide TOC

Once a "complete" mooring has been designed, which includes, from top to

bottom, floatation, wires, fasteners and instruments, and an anchor, and appropriate environmental

conditions have been entered (i.e. current profile(s)) that either exceed the height

of the mooring (for sub-surface) or extend to the surface (for shallow or surface moorings), then a

"solution" can be sought. If a time series of current profiles (time dependent

solution) has been loaded, then the user will have to specify at which time a solution is sought. The

"Select Time" window shows the start and end times of the time dependent currents (user specified

units). An "Edit Time" option allows the user to edit the approximate (closest) time for which a

solution is sought. This exact time will be displayed on the 3-D mooring plot. If a single current

profile has been set (not a time dependent solution), then this menu is not displayed.

Once a "complete" mooring has been designed, which includes, from top to

bottom, floatation, wires, fasteners and instruments, and an anchor, and appropriate environmental

conditions have been entered (i.e. current profile(s)) that either exceed the height

of the mooring (for sub-surface) or extend to the surface (for shallow or surface moorings), then a

"solution" can be sought. If a time series of current profiles (time dependent

solution) has been loaded, then the user will have to specify at which time a solution is sought. The

"Select Time" window shows the start and end times of the time dependent currents (user specified

units). An "Edit Time" option allows the user to edit the approximate (closest) time for which a

solution is sought. This exact time will be displayed on the 3-D mooring plot. If a single current

profile has been set (not a time dependent solution), then this menu is not displayed.

Initiated from the Main Menu for a

time independent solution or by clicking "OK" in the "Select Time" window for a time dependent

solution, the mathematical solution is evaluated using an iterative approach, repositioning the

mooring components in the water column (i.e. velocity and density profiles) according to the wire

angle and orientation after each iteration. First, a solution is sought with a zeroed velocity profile. This

provides an estimate of the component heights under tension, but without currents. Then, a solution is sought

with the mooring forced by the specified velocity profile. The

Matlab® Command Window, (shown here) displays a "dot"

for each iteration. Once the vertical position of the top most mooring element (usually a floatation

device) changes by less than 0.01 m between iterations, it is assumed a solution has been found.

Strongly sheared current profiles may make convergence difficult. The type of solution is then

displayed (either a surface or sub-surface mooring), and the total, vertical, and horizontal tensions

[measured in kg] acting on the anchor are displayed, followed by "estimates" of the safe anchor mass

necessary to hold the mooring in position, based on both the vertical (VWa) and horizontal (HWa)

tensions according to 1.5*(VWa + HWa/0.6), which incorporates drag and lift safety factors, and is

adopted from the Mooring Group at the Woods Hole Oceanographic Institution. Also displayed are the

equivalent dry anchor masses in terms of both steel and concrete. After a solution has been found,

the tensions at and positions of all major mooring components and at the ends of each wire segment

can be displayed by clicking the Display Mooring Elements button from the

Main Menu.

Initiated from the Main Menu for a

time independent solution or by clicking "OK" in the "Select Time" window for a time dependent

solution, the mathematical solution is evaluated using an iterative approach, repositioning the

mooring components in the water column (i.e. velocity and density profiles) according to the wire

angle and orientation after each iteration. First, a solution is sought with a zeroed velocity profile. This

provides an estimate of the component heights under tension, but without currents. Then, a solution is sought

with the mooring forced by the specified velocity profile. The

Matlab® Command Window, (shown here) displays a "dot"

for each iteration. Once the vertical position of the top most mooring element (usually a floatation

device) changes by less than 0.01 m between iterations, it is assumed a solution has been found.

Strongly sheared current profiles may make convergence difficult. The type of solution is then

displayed (either a surface or sub-surface mooring), and the total, vertical, and horizontal tensions

[measured in kg] acting on the anchor are displayed, followed by "estimates" of the safe anchor mass

necessary to hold the mooring in position, based on both the vertical (VWa) and horizontal (HWa)

tensions according to 1.5*(VWa + HWa/0.6), which incorporates drag and lift safety factors, and is

adopted from the Mooring Group at the Woods Hole Oceanographic Institution. Also displayed are the

equivalent dry anchor masses in terms of both steel and concrete. After a solution has been found,

the tensions at and positions of all major mooring components and at the ends of each wire segment

can be displayed by clicking the Display Mooring Elements button from the

Main Menu.

After the solution has been found, the three-dimensional mooring shape is

plotted, and a Modify Plot menu is displayed that will allow you to modify the

plot (i.e. plot title, orientation, view, etc.). The view angles are standard three-dimensional

controls, explained by the help available for the "plot3" and "view" commands. Alternately, the view

of the mooring can be modified by clicking the  button, and then using the mouse to click-and-drag on the

figure axes to rotate the view. (The help for the

Matlab® command "rotate3d" is automatically

displayed in the Matlab® Command Window when

this button is clicked.) The U and V velocity profiles

can be plotted against the Y and X faces of the plot, respectively, normalized to the scale of the

axes by clicking on the "Plot Velocity Profiles" button.

button, and then using the mouse to click-and-drag on the

figure axes to rotate the view. (The help for the

Matlab® command "rotate3d" is automatically

displayed in the Matlab® Command Window when

this button is clicked.) The U and V velocity profiles

can be plotted against the Y and X faces of the plot, respectively, normalized to the scale of the

axes by clicking on the "Plot Velocity Profiles" button.

When the water depth (as defined by the height of the velocity profile) is

near or at the top of the mooring (i.e. in the case of a surface mooring), then a blue wave field is

plotted. Additional plot controls can be entered manually from the

Matlab® Command Window. For

example, axis format and titles can be modified using the

Matlab® commands for "axis" and

"xlabel"/"ylabel". Similarly, additional text or information can be added to the plot using standard

Matlab®

commands. The plot can be printed by clicking the "Print" button in the Modify Plot menu or from the "File" pull-down menu available at the top of the Figure

window, sending the displayed figure to the "default" printer. If you do

not have a default printer that Matlab® can

print to, DO NOT click on the "Print" button.

Alternately, the plot (and for that matter any of the displayed "figures") can be printed to a file

using the "print -d device filename" option of the

Matlab® "print" command.

When the water depth (as defined by the height of the velocity profile) is

near or at the top of the mooring (i.e. in the case of a surface mooring), then a blue wave field is

plotted. Additional plot controls can be entered manually from the

Matlab® Command Window. For

example, axis format and titles can be modified using the

Matlab® commands for "axis" and

"xlabel"/"ylabel". Similarly, additional text or information can be added to the plot using standard

Matlab®

commands. The plot can be printed by clicking the "Print" button in the Modify Plot menu or from the "File" pull-down menu available at the top of the Figure

window, sending the displayed figure to the "default" printer. If you do

not have a default printer that Matlab® can

print to, DO NOT click on the "Print" button.

Alternately, the plot (and for that matter any of the displayed "figures") can be printed to a file

using the "print -d device filename" option of the

Matlab® "print" command.

If the mooring is anticipated to be a SURFACE mooring

(i.e. the mooring height is expected to exceed the water depth and the top floatation device will

float at the ocean surface), then one can expect a much higher number of iterations before a

converged solution is found. This is because the solution does not know a priori how much of the

buoyancy of the top floatation component(s) to use to keep the mooring "up". In fact, if the

model estimates that the top floatation components provide virtually no lifting buoyancy to the

remainder of the mooring (i.e. as in the case of example mooring moor002.mat (shown to the left) when

the current speeds are reduced), especially for S-mooring configurations, then the solution may

NOT easily converge (i.e. tensions are near zero).

In version 2.5 I have modified the code in an important way, for surface floating moorings. Previously (v2.4)

if the top float was not needed to lift any submerged elements, then the top floatation segments were removed.

This, however, is not realistic. Surface floats must support themselves, and even if there is no tension from below,

the surface float must be alound to just float on the surface, supporting its own weight. Floats typically take between

10 - 30% of their buoyancy just to float themselves, with smaller floats taking more buoyancy (30%) and larger floats taking

less (10-15%). However, this still is tricky for the code to solve, as a surface float may not need to "lift" the submerged mooring,

but the surface float will contribute (important) lateral drag.

The database for floats now includes the weight of float, such that the minimum percentage of

the float used is weight/buoyancy. If more is needed, then it is (weight+tension)/buoyancy, where only the vertical part of

tension under the float is considered. Under weak currents this is still a difficult convergence problem, so the light mooring solutions in

weak current conditions are subject to larger errors. For old saved moorings, that do not include a value for the weight of

the float, a nominal value of weight=0.15 * buoyancy is used.

An example of a

mooring which poses grave convergence problems for the solution algorithm is a simple Polypropylene

mooring with multiple small float/Polypropylene segments, far exceeding the water depth (e.g. moor003.mat). The small

tensions and large changes in the drag to buoyancy ratio with only tiny adjustments to the surface

float buoyancy prevent a "stable" solution, even though we know the mooring can exist. Trailing a

line and floats on the surface tends to have horizontal tensions only, and the vertical position and

vertical tensions are naturally quite unstable. If you need to know the position of such a mooring, then

simply add the known length of the trailing segments to the part of the mooring which has only a

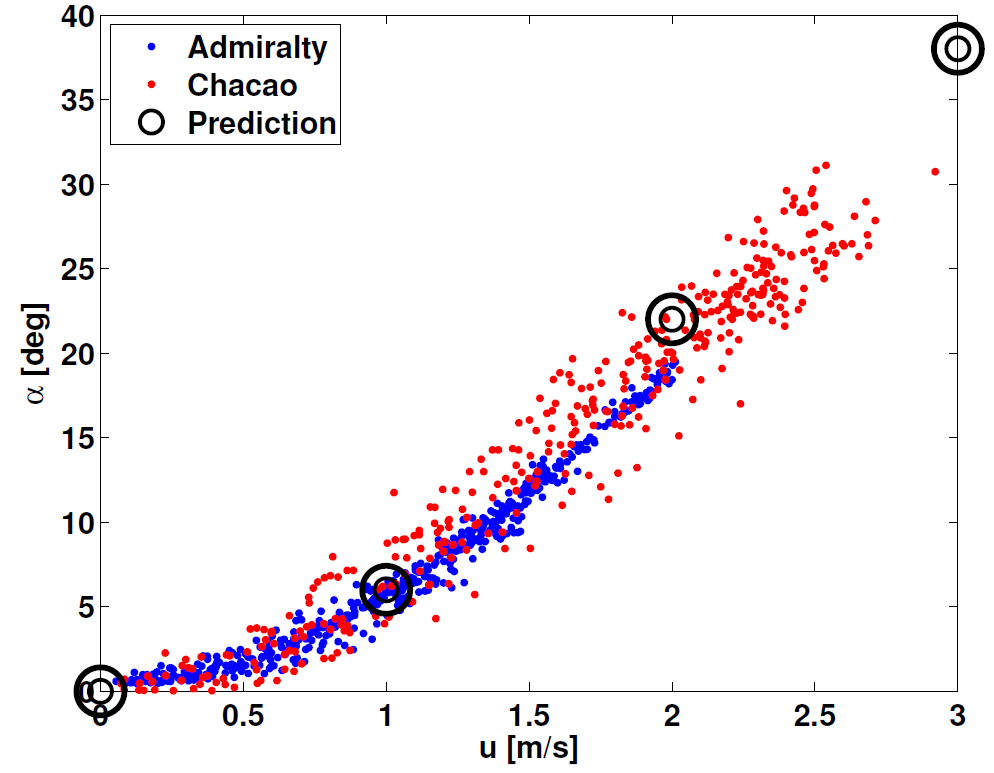

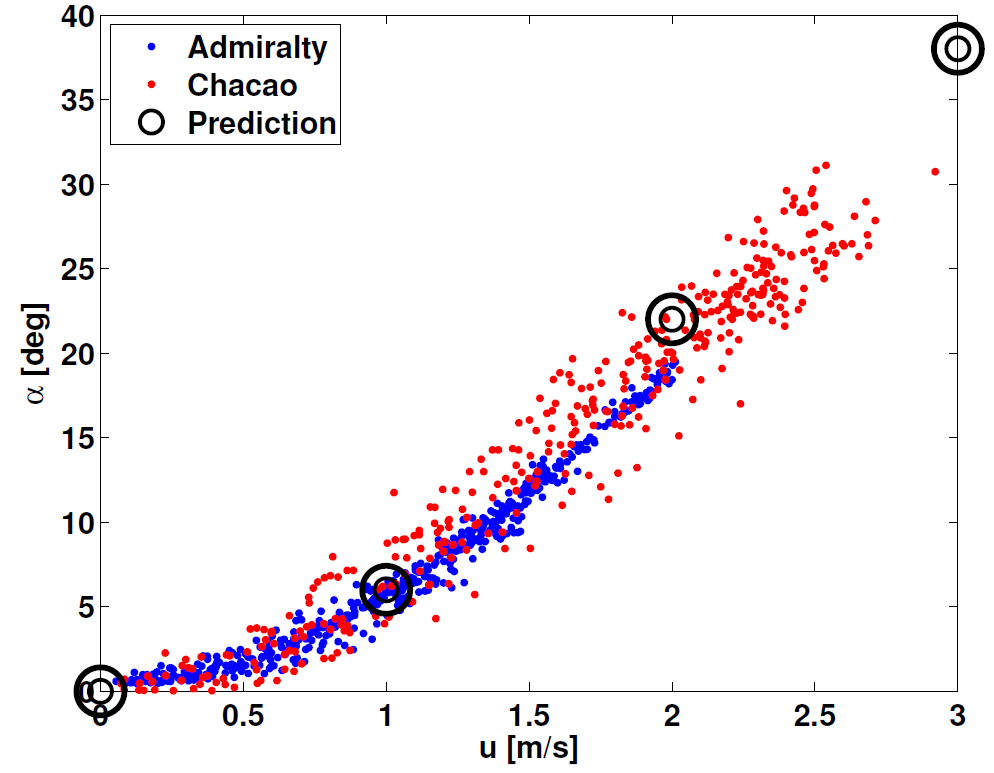

float and submerged components.